Baoji Hanz Metal Material Co., Ltd. has long been committed to the research of nickel-titanium alloy materials. It has unique and professional technology for Nickel Titanium Alloy straight wire and can provide you with the most professional technical and knowledge answers.

Products Description

Basic knowledge of Nickel Titanium Alloy straight wire

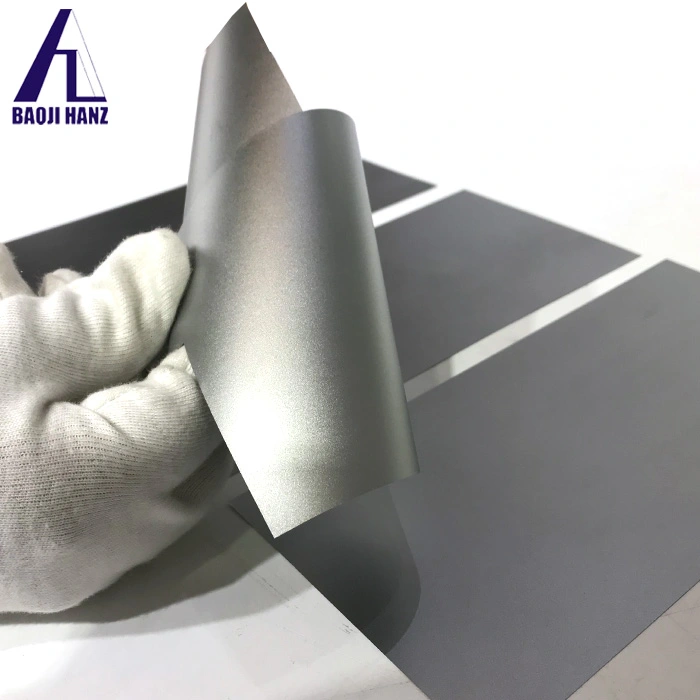

Nickel Titanium Alloy straight wire, composed of nickel (Ni) and titanium (Ti), is a functional material with shape memory effect and superelasticity. It is made into straight wire form through cold drawing or heat treatment and is widely used in fields that require special mechanical properties.

Advantage of Nickel Titanium Alloy straight wire

- Unique mechanical adaptability: Superelasticity reduces stress during orthodontic treatment, and shape memory function simplifies complex structural designs.

- Reliability: Strong fatigue resistance and not prone to breakage even after long-term use.

- Biological safety: Meets medical implant standards and reduces the risk of allergies.

- Processing convenience: Performance can be adjusted through cold working or heat treatment to meet different application requirements.

| The Max recovery stress | 600 MPa |

| Modulus of elasticity | Austenite 83 Gpa |

| Tensile strength | 800-1500MPa |

| Phase transition temperature (Afc) | -50℃ ~ +120℃ |

| Density | 6.45g/cm³ |

| Processing Service | Bending, Welding, Decoiling, Cutting |

| surface | polished |

| Standard | ASTM F2063 |

Characteristics and Attributes

-Shape memory effect: The preset shape can be restored at a specific temperature, and the shape can be restored after low-temperature deformation and heating.

- Super elasticity: It can automatically recover after being deformed by external force, and the elastic deformation range far exceeds that of traditional metals.

- Biocompatibility: Non-toxic, good compatibility with human tissues, suitable for medical implantation.

- Corrosion resistance: A titanium oxide layer forms on the surface, which has strong resistance to body fluids, acids and alkalis corrosion.

- Mechanical properties: High strength, good flexibility, and its performance is significantly affected by temperature.

The chemical composition of Nickel Titanium Alloy straight wire

| Element | Mass percentage |

| Ni | 54.5-57.0 |

| C |

≤0.040 |

| Co |

≤0.050 |

| Cu |

≤0.010 |

| Cr |

≤0.010 |

| H |

≤0.005 |

| Fe |

≤0.050 |

| Nb |

≤0.025 |

| N |

≤0.005 |

| O |

≤0.040 |

| Ti | Margin |

The application environment of Nickel Titanium Alloy straight wire

- Electronic devices: connectors, sensors (temperature or stress triggered).

- Industry: Automatic reset components and anti-vibration elements in mechanical devices.

|

|

|

|

|

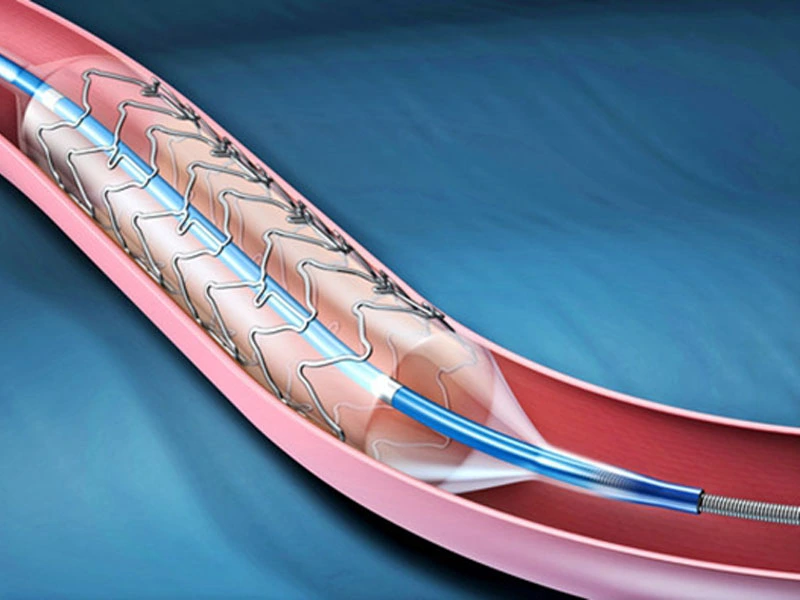

- Medical: Orthodontic archwires, vascular stents, minimally invasive surgical instruments (such as thrombus filters).

|

|

ABOUT US

Baoji Hanz Metal Material Co., Ltd. is located in the Titanium Valley Nonferrous Metals Base of Baoji City, China. The company is equipped with a complete set of precise production and processing equipment, solid technology, and a professional sales and after-sales team. Main business: Nickel-titanium memory alloy materials; Design, manufacture, production and service of industrial kilns and mechanical equipment. The company is equipped with advanced R&D, production and testing facilities.

The company is committed to the business philosophy of "technological leadership, excellent quality, steady development and win-win cooperation", and is willing to seize business opportunities together with colleagues from all walks of life to create a bright future.

Our Certificate

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, SGS ,TUV guidelines and our stringent quality control system.

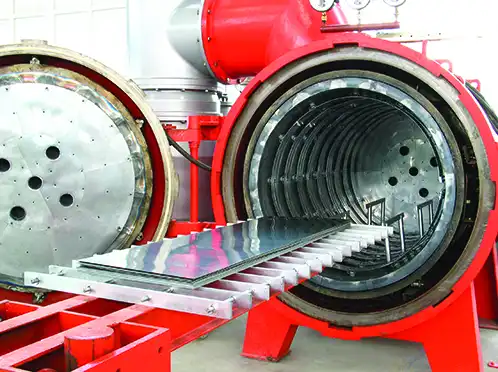

Our equipment

We have professional equipment reserves regarding Nickel Titanium Alloy straight wire

Baoji Hanz Metal Material Co., Ltd. welcomes your calls and email for any technical and after-sales issues regarding Nickel Titanium Alloy straight wire 24 hours a day.

OEM Services

We provide comprehensive OEM services for clients who require customized solutions. From adjustments to size and coating to custom packaging, we work closely with you to create a product that fits your exact specifications. Whether you're developing a new product or need large quantities for a specific application, we offer flexibility to meet your needs.

Frequently Asked Questions (FAQ)

Q1: What is the material of the Nickel Titanium Alloy straight wire ?

A1: The Nitrex Guidewire is made from high-quality nitinol shape memory alloy, offering superior strength and flexibility.

Q2: Can I customize the guidewire length and diameter?

A2: Yes, we offer customization options based on your specific requirements. Please contact us for more details.

Q3: Does the guidewire come with certification?

A3: Yes, all of our products are certified with ISO9001:2015, ISO13485:2016, and EU CE safety standards.

Contact Us

The Nickel Titanium Alloy straight wire is the ideal solution for professionals seeking a high-quality, reliable, and cost-effective Nitinol wires for medical procedures. Manufactured to the highest standards with the latest technology, it ensures optimal patient outcomes. With competitive pricing, OEM services, and certifications, you can trust Baoji Hanz Metal Material Co., Ltd. to meet your needs.For more information about our product, including pricing, customization options, and bulk orders, please feel free to reach out to us:

Email: baojihanz-niti@hanztech.cn

We are here to assist you and look forward to your inquiry!

_1740043052871.webp)

.webp)

.webp)

.webp)