Alloy Titanium Nickel Wire Description:

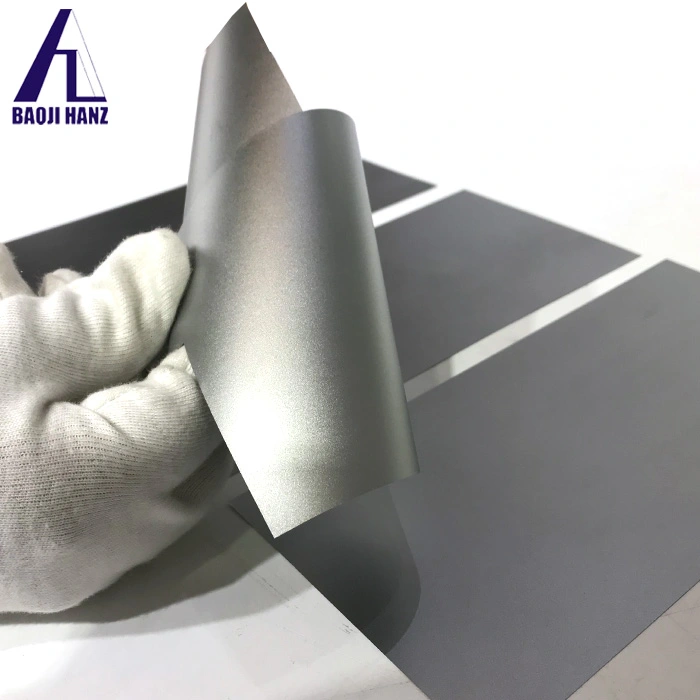

Alloy titanium nickel wire, also known as NiTi wire, is a nickel titanium alloy renowned for its shape memory effect, superelasticity, excellent fatigue resistance, and corrosion resistance. After deformation, it can recover to its original shape at specific transformation temperatures.

Baoji Hanz Metal Materials Co., Ltd. is a qualified supplier specializing in the customization of nickel titanium alloy materials and products, offering high-performance superelastic and shape memory alloy titanium nickel wire that fully comply with the ASTM F2063 standard.

Whether you need wires with customized transformation temperatures, strict diameter tolerances, or specific surface treatments, we can provide customized solutions based on your application requirements.

Properties of Alloy Titanium Nickel Wire:

1. Precisely smelted with adjustable component percentage

2. Can be customized for phase transition temperature range according to different applications

3. Possesses stable shape memory and superelasticity

4. The guidewire has excellent straightness and elasticity, with good anti-bending performance

Specification

|

Material Grade |

NiTi |

|

Wire Shape |

Round Wire |

|

Diameter Range(mm) |

0.1-2.5 |

|

Standards |

ASTM F2063,GB 24627 |

|

Diameter Tolerance |

±0.001mm |

|

Surface Finish |

Black Oxidized, Lightly Oxidized, Bright, Ultra Bright, Polished, Clean |

|

Delivery Condition |

Straightened superelastic , Cold-worked |

|

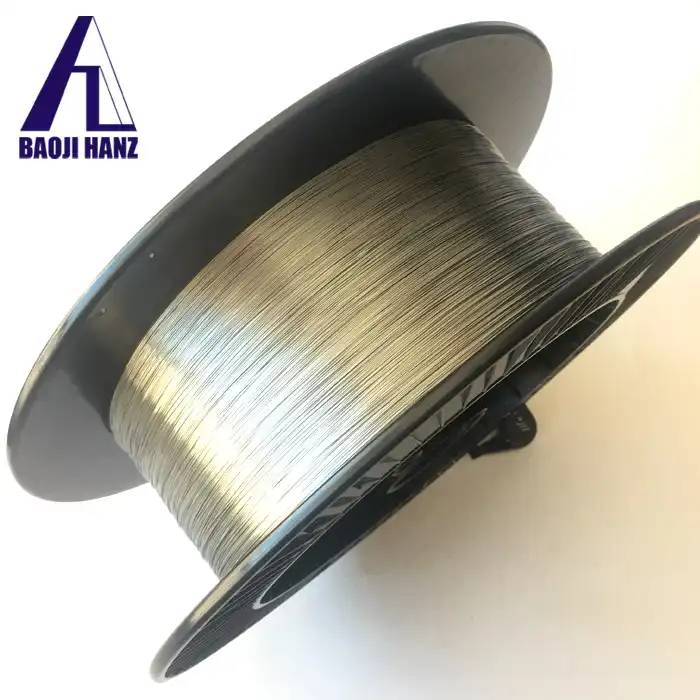

Supply Form |

Spool wound, Straight |

Chemical Composition

|

Chemical Composition: ASTM F2063 |

|

|

Element |

Mass Percentage (wt%) |

|

Ni |

54.5-57.0 |

|

C |

≤0.040 |

|

Co |

≤0.050 |

|

Cu |

≤0.010 |

|

Cr |

≤0.010 |

|

H |

≤0.005 |

|

Fe |

≤0.050 |

|

Nb |

≤0.025 |

|

N |

≤0.005 |

|

O |

≤0.040 |

|

Ti |

balance |

Mechanical Properties

|

Mechanical Properties: ASTM F2063 |

|||||

|

NiTi Alloy Code |

Straightened Superelastic Condition (SE) |

||||

|

Tensile Strengthσ,Mpa |

Elongationδ,% |

Upper Plateau Stress σ, MPa |

Residual Strain, % |

Active Af Temperature, ℃ |

|

|

D |

≥1300 |

≥10 |

≥480 |

<0.5 |

10±7 |

|

C |

≥1150 |

≥10 |

≥440 |

<0.5 |

17±7 |

|

S |

≥1000 |

≥10 |

≥400 |

<0.5 |

25±5 |

Nitinol Wire Production Process

Raw material → Mixed ingredients → Vacuum melting → Sampling analysis after furnace → Hot forging → Hot rolling to 8MM → Pickling → Wellbore annealing (heat treatment) → Wire drawing → Wellbore annealing (heat treatment) → Sampling and testing → Water tank drawing → Continuous annealing → Finished product inspection and testing → Packing → Final shipment

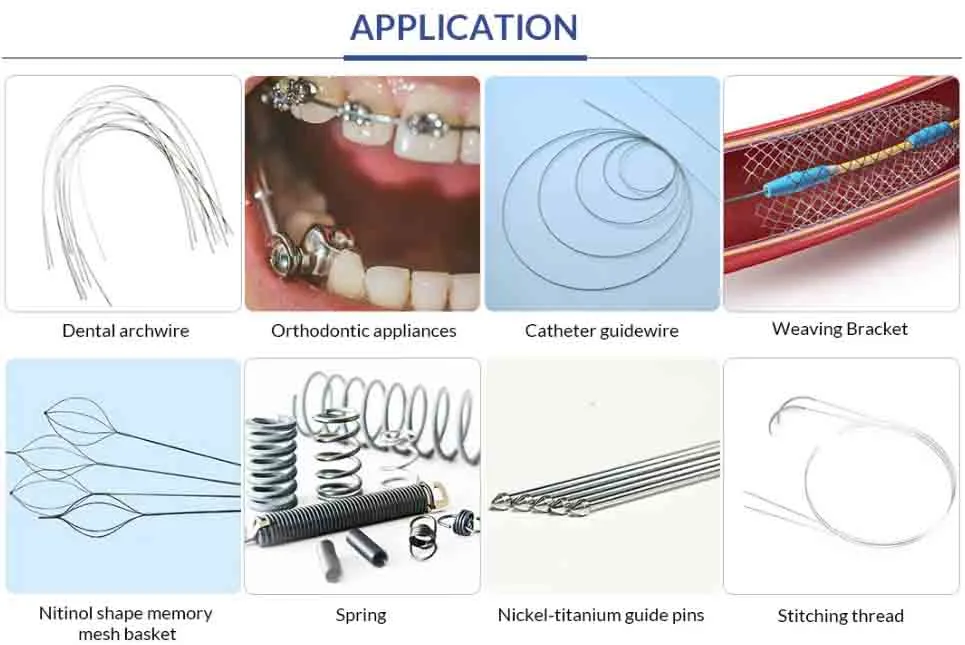

Application

Contact us

Baoji Hanz Metal Material Co., Ltd.

Gaoxin Avenue, BaoJi city, ShaanXi province China

Tel: 86-917-3258889

Mobile, Whatsapp,Wechat: +8618091719909

Email:baojihanz-niti@hanztech.cn

_1740043052871.webp)

.webp)

.webp)

.webp)

.webp)