Baoji Hanz Metal Material Co., Ltd.: Your Trusted Nitinol SMA Wire Manufacturer & Supplier

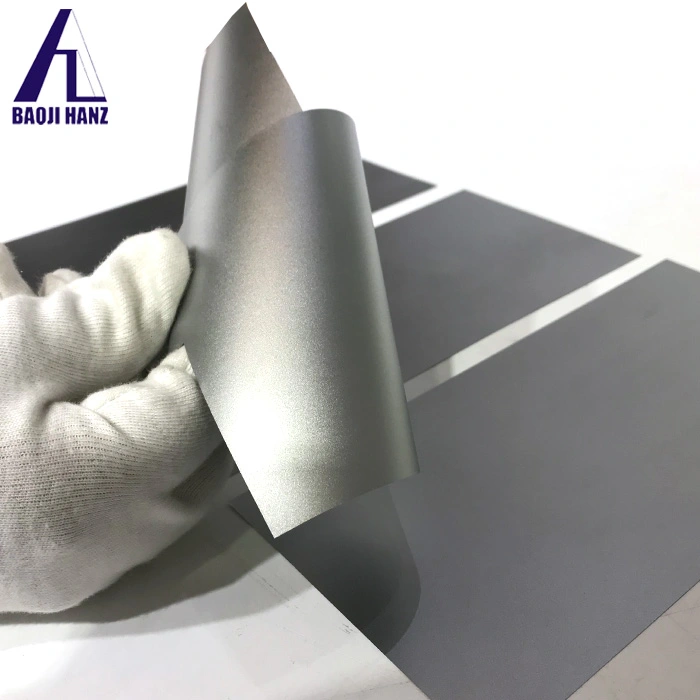

Baoji Hanz Metal Material Co., Ltd. mainly focuses on rare metal materials and products, especially excelling in the field of nickel-titanium alloys. It has unique and professional technical advantages in the production of Nitinol SMA Wire.

Nitinol SMA Wire Basic Knowledge

Nitinol SMA Wire has unique properties and wide applications. It is mainly a shape memory alloy wire material composed of nickel and titanium in an atomic ratio of approximately 1:1.

Production Process

Instructions for each step

1. Raw material preparation

2. Smelting and casting

3. Hot working

4. Cold drawing

5. Annealing treatment

6. Surface treatment

7. Straightening and sizing

Specifications

| Processing Service |

Bending, Welding, Decoiling, Cutting, Punching |

| Feture | Corrosion resistance, biocompatibility, superelasticity, shape memory effect |

| Ti (Min) | 50 |

| Elongation | 25-50% |

| Melting point | 1310°C |

| Tensile strength | 800-1500MPa |

| Phase transition temperature (Afc) | -50℃ ~ +120℃ |

| Density | 6.45g/cm³ |

| MOQ | 1kg or 100meters |

| standard | ASTM F2063 |

Chemical Composition

| Element | Mass percentage |

| Ni | 54.5-57.0 |

| C |

≤0.040 |

| Co |

≤0.050 |

| Cu |

≤0.010 |

| Cr |

≤0.010 |

| H |

≤0.005 |

| Fe |

≤0.050 |

| Nb |

≤0.025 |

| N |

≤0.005 |

| O |

≤0.040 |

| Ti | Margin |

Application

Our Certificates

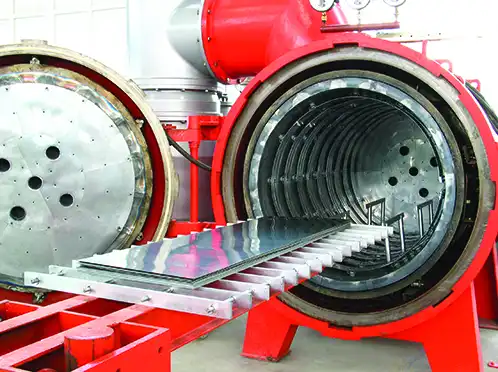

Our Equipment

Packaging/Transportation/Payment Method

OEM Services

1. 24-hour product technology and consultation;

2. Packaging can be customized;

3. Customized Logo;

4. Multi-channel payment methods;

5. Customization based on provided drawings is available to meet the diverse needs of customers.

FAQ

Q1: What is the material of the Nitinol SMA Wire ?

A1: The Nitrex Guidewire is made from high-quality nitinol shape memory alloy, offering superior strength and flexibility.

Q2: Can I customize the guidewire length and diameter?

A2: Yes, we offer customization options based on your specific requirements. Please contact us for more details.

Q3: Does the guidewire come with certification?

A3: Yes, all of our products are certified with ISO9001:2015.

Q4:What is the minimum order quantity for the product?

A4:If in stock, the minimum order quantity is 1kg or 100meters. If not, it depends on the specifications.

Contact Us

We have been deeply engaged in the nickel-titanium wire field for many years. With advanced technology and strict quality control, we create high-quality Nitinol SMA Wire products that combine shape memory effect, super elasticity and biocompatibility. Whether you have product needs, technical inquiries or cooperation intentions, please feel free to contact us at any time!

Email: baojihanz-niti@hanztech.cn

We are here to assist you and look forward to your inquiry!

_1740043052871.webp)

.webp)

.webp)