Products Description

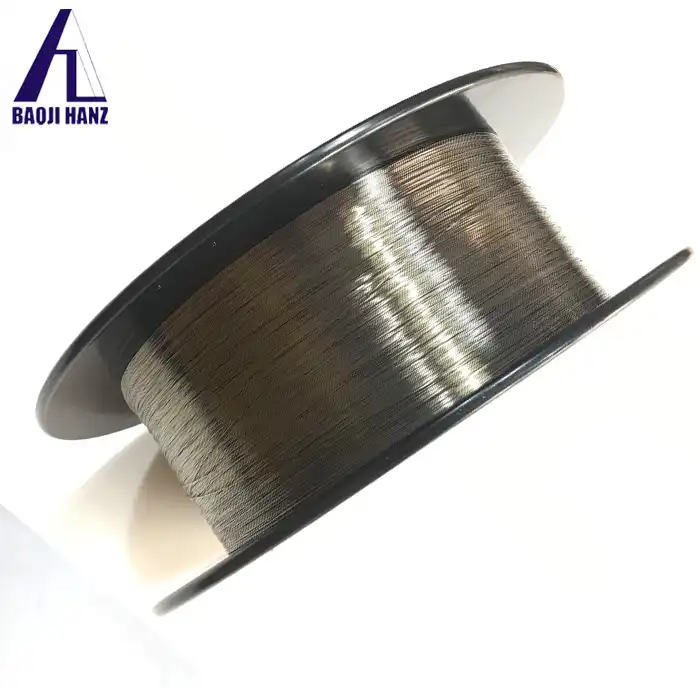

Nitinol Superelastic Wire 0.1mm - Medical & Industrial Grade (0.1mm-5.0mm Customizable)

High-performance shape memory alloy wire with superelasticity, biocompatibility & corrosion resistance for precision applications.

Core Parameters Of Nitinol Superelastic Wire 0.1mm

|

Product Name |

nitinol superelastic wire 0.1mm price per kg |

| Size | 0.1mm |

| Af temperature | 10-15 degree celsius |

| Surface | polishing surface and black surface |

| Standard | ASTM F 2063-12 |

| Certification | ISO9001 :2015 |

| Feature | shape memory and super-elastic properties |

| MOQ | 2 kg |

- Medical Grade: ASTM F2063, ISO 5832-11, GB/T 24627 - Industrial Grade: ASTM B348, GB/T 30030, EN 10204

Content Of Nitinol Superelastic Wire 0.1mm Components

Nickel and titanium are the main components of the nitinol superelastic wire 0.1mm in this product.

|

The Current production Line |

||||

|

Chemical element |

Af range |

Available production Line |

Usage |

Sample |

|

Nickel 55% Titanium 45% |

0℃to 100℃ |

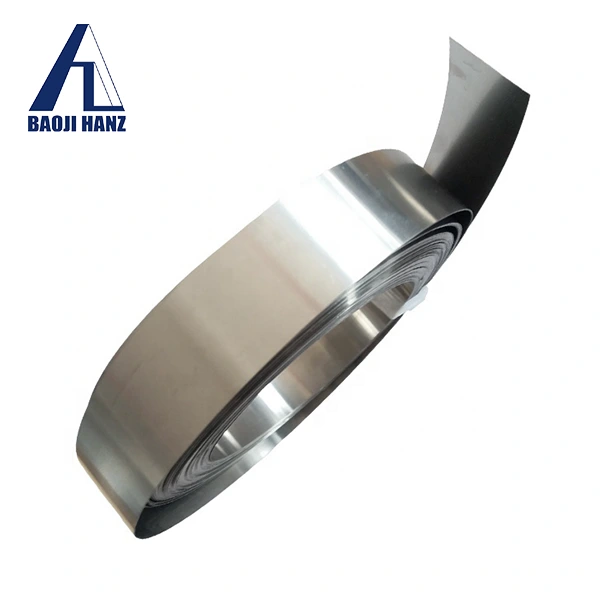

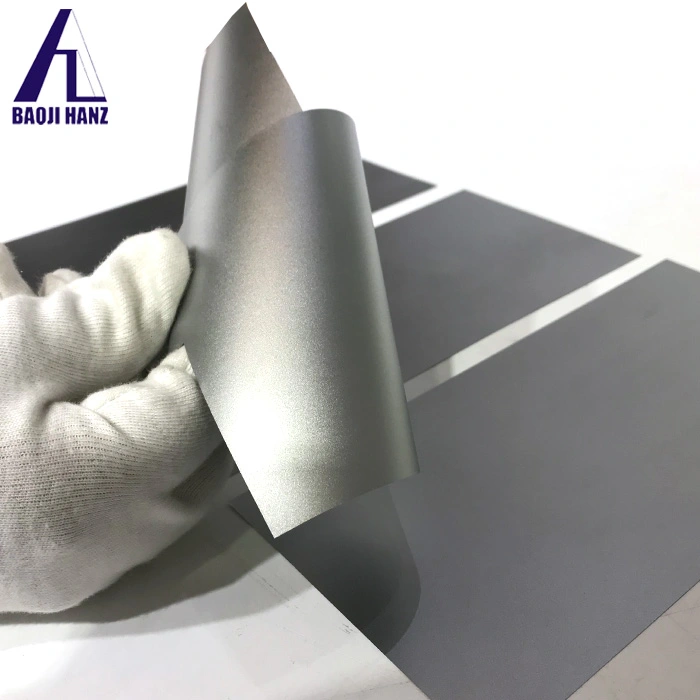

Rod&wire,Plate&sheet,Strip&foil |

Medical&Industry |

Medical&Industry |

|

Nickel 55% +V +Ti |

Subzero 30℃ to -5 ℃ |

Rod&wire,Plate&sheet |

industry |

On stock |

|

Nickel 55% +Fe +Ti |

||||

|

Nickel 55%+Cr +Ti |

||||

|

Nickel 55% +Hf +Ti |

Above 100C |

ingot |

industry |

updating |

Core Advantage

-Superelasticity & Shape Memory: No permanent deformation after repeated bending, ensures long-term reliability in cyclic use.

-Medical-Grade Biocompatibility: Non-toxic, hypoallergenic, suitable for implants and medical devices (e.g., guidewires, stents).

-Extreme Corrosion Resistance: Withstands harsh environments (chemicals, body fluids, industrial humidity) without degradation.

- Customizable Specifications: Tailor diameter, transition temperature, surface finish to match specific application needs.

-High Fatigue Strength: Endures continuous mechanical stress, ideal for high-cycle components (springs, actuators).

Application

1. In the medical field: guidewires, catheters, vascular stents, minimally invasive surgical tools, bone fixation devices;

2. In the industrial field: micro springs, flexible sensors, robot joints, lightweight actuators, thermal expansion compensators, connector pins, shock absorption components;

0.1mm superelastic nickel-titanium wire usage guide:

Focus on ultra-precise applications, with the core used in medical ultra-fine interventional guidewire cores, micro medical device elastic wires, precision instrument elastic probes/micro springs, flexible driving wires for micro robots, and electronic micro valve triggers;

How Does Nitinol Work?

Nitinol operates via reversible austenite-martensite phase transformations: stress-induced (room temp above Af, ~8% recoverable deformation=superelasticity) or temperature-induced (heat/cool to set/deform/recover=shape memory effect).

Quality Control

- Full production process inspection (raw material → forging → drawing → heat treatment)

Technical Support and Services

1. Personalized Service: Optimize technical parameters according to your application requirements.

2. Technical Documentation: Provide material reports and technical guidance.

3. Delivery and Delivery Time: Standard-sized products are delivered within 7 to 15 days; custom orders take 20 to 40 days.

4. After-sales Service: A professional engineering team will address technical issues within 24 hours.

We look forward to receiving your personalized requests and conducting detailed consultations. If you have any questions, please contact us at baojihanz-niti@hanztech.cn - we are a reliable partner that provides high quality nickel titanium alloy products.

_1749798209934.webp)

.webp)

.webp)