Baoji Hanz Metal Material Co., Ltd.: Your Trusted Nickel titanium alloy flat wire Manufacturer & Supplier

Baoji Hanz Metal Material Co., Ltd is professional manufacture of Nitinol product, we have been in this field for more than 10 years. With top quality raw material and advanced process equipment, different shape of Nitinol products are supplied by us. especiall Nitinol flat wire (nickel titanium alloy flat wire), nitinol round wire, nitinol bar, nitinol sheet and nitinol tubes etc.

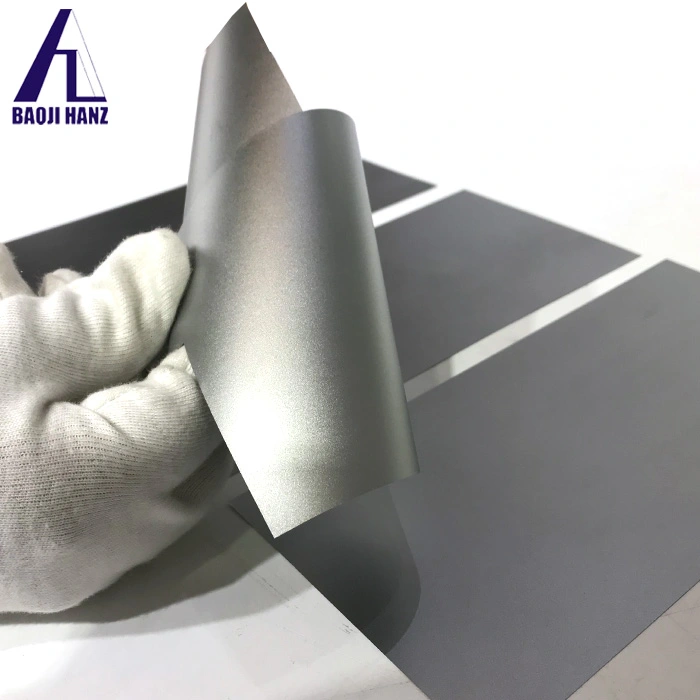

Nickel Titanium Alloy Flat Wire Product description

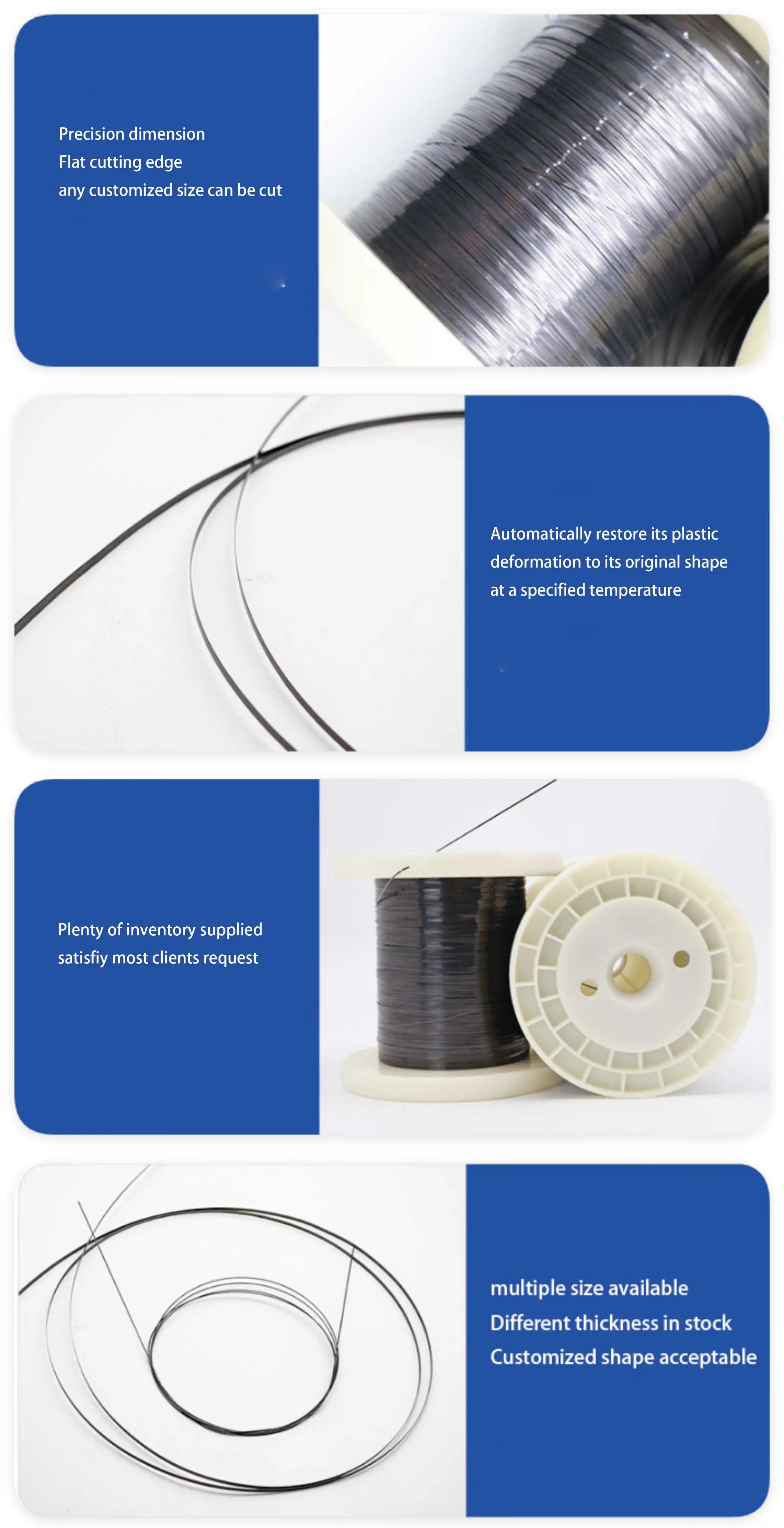

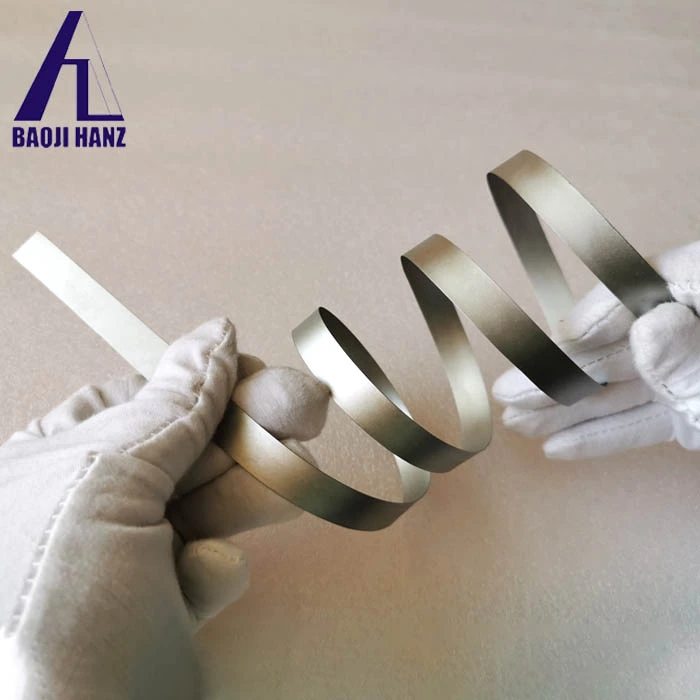

Nickel titanium alloy flat wire is produced by nickel and titanium material alloy, it contains 50-55% nickel and 45-50% titanium, that makes nickel titanium alloy wire owns perfect propeties from nickel and titanium, we called it unique shape memory property and super elastic property.

Due to advantages of shape memory and super elastic, nitinol flat wire shows great potenial in virous of fields, like medical fields, aerospace field, industry aera and daily life. The phase transition temperature (Af) of nickel titanium alloys can be precisely controlled by adjusting the composition ratio and heat treatment process, which is the core of their functional characteristics. Compared with ordinary round wires, the flat wire shape provides a larger contact area and a better combination of mechanical properties, making it particularly suitable for application scenarios that require specific surface contact or guiding performance.

|

|

|

Chemical composition

| Item | Ni | C | Co | Cu | Cr | H | Fe | Nb | N | Ti |

| content | 54-55% | 0.05 | 0.05 | 0.01 | 0.01 | 0.05 | 0.05 | 0.05 | 0.025 | balance |

Main properties

| Item | unit | value | |

| Density | g/cm3 | 6.4-6.5g | |

| Melting point | ℃ | 1310 | |

| Hardness | Martensite | HV | 180-200 |

| Austenite | HV | 200-350 | |

| Tensile strength | Annealed | Mpa | 850 |

| Processed | Mpa | 1900 | |

| Yield strength | Martensite | Mpa | 7-140 |

| Austenite | Mpa | 195-690 | |

| Elongation rate | Annealed | % | 25-50 |

| Processed | % | 5-10 | |

| Phase transition temperature | ℃ | -100-100 | |

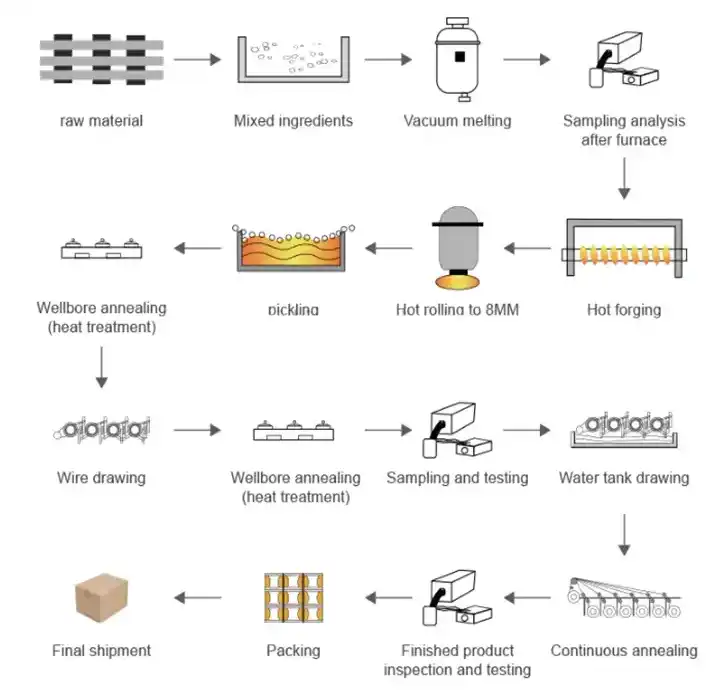

Processing progress

The typical production process includes:

preparation of high-purity alloy ingots by vacuum induction melting (VIM) or vacuum arc remelting (VAR) → hot rolling or hot extrusion into billets → multi pass cold rolling forming → intermediate annealing treatment → precision rolling to target size → final heat treatment (aging treatment) → surface treatment (such as electrolytic polishing, acid washing or coating) → laser or optical dimension detection → packaging.

Among them, precision rolling and heat treatment are the key factors determining the final performance of flat wire. Strict control of impurities such as oxygen and carbon is required during the production process, as these elements significantly affect the phase transition temperature and fatigue life of the material.

Characteristics

Based on their functional characteristics, Nickel titanium flat wires are mainly divided into three kinds:

Hyperelastic type (with Af lower than the operating temperature at room temperature, exhibiting significant hyperelasticity and a strain of over 8%),

Shape memory type (with Af higher than the operating temperature at room temperature, requiring heating above the phase transition temperature to restore shape)

Heat treatable type (with performance adjustable through subsequent heat treatment). In the medical field, super elastic nickel titanium flat wire is widely used in vascular stents, orthopedic implants, and dental orthodontic equipment; In the aerospace field, shape memory flat wires are used for expandable structures and pipeline connectors.

Application

From the perspective of size specifications, medical nickel titanium flat wires typically have a thickness between 0.1-0.5mm and a width between 0.5-3.0mm, depending on application requirements. e.g: for vascular stents are usually thinner (0.1-0.2mm thick), for orthopedics are thicker (0.3-0.5mm thick). Industrial nitinol flat wire may be larger in size to meet higher mechanical performance requirements.

Why choose us?

FAQ

Q1: Are you a manufacturer or a trading company?

A:1 We are a direct manufacturer with many years of experience in the production of nickel and titanium.

Q2: What is your payment method?

A2: Common payment methods: Telegraphic transfer, Western Union, PayPal. If you need other payment methods, please contact us.

Q3: What aspects of data do buyers need to provide before product quotations?

A3: To provide an accurate quotation, the following materials need to be sent:

1.material

2. Standard

3. Specifications

4. Data

5. Tolerance

Q4: Do you offer custom manufacturing?

A4: Yes! We can customize nickel-titanium products according to the drawings and samples provided by customers.

Contact us

How to get an offer?

If you are interested in buying nickel titanium alloy flat wire, feel free to send us inquiry to email: baojihanz-06@hanztech.cn

or call us on :+8618329678518

we will be at service all the working time! (08:30-18:00)

_1740043052871.webp)

.webp)

.webp)

.webp)