How Does Corrosion-Resistant Nitinol Wire Perform Under Extreme Temperature Conditions?

2025-06-27 22:28:29

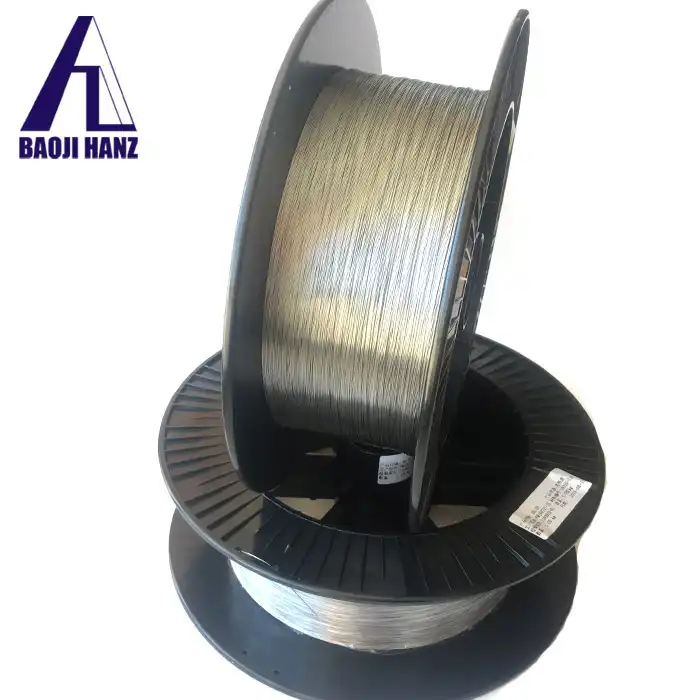

Corrosion-Resistant Nitinol Wire represents one of the most remarkable engineering materials of our time, combining the unique properties of nickel-titanium alloys with exceptional resistance to environmental degradation. When subjected to extreme temperature conditions, this specialized wire demonstrates extraordinary performance characteristics that make it indispensable across medical, industrial, and aerospace applications. The material's ability to maintain structural integrity, shape memory properties, and superelastic behavior under challenging thermal environments sets it apart from conventional materials. Understanding how Corrosion-Resistant Nitinol Wire responds to temperature extremes is crucial for engineers and designers who rely on consistent performance in demanding applications where traditional materials would fail or degrade rapidly.

Temperature-Dependent Mechanical Properties of Corrosion-Resistant Nitinol Wire

Shape Memory Effect Stability at High Temperatures

Corrosion-Resistant Nitinol Wire exhibits remarkable shape memory characteristics that remain stable even when exposed to elevated temperatures reaching up to 100°C. The material's phase transition temperature (Afc) ranges from -20°C to 100°C, allowing it to maintain its shape memory properties across a wide thermal spectrum. At higher temperatures, the austenite phase becomes more stable, which enhances the wire's ability to recover its predetermined shape when thermal activation occurs. The mechanical polishing surface treatment employed by Baoji Hanz Metal Material Co., Ltd. further enhances this stability by reducing surface irregularities that could compromise performance under thermal stress. During high-temperature exposure, the wire's tensile strength of 850-1500 MPa remains largely intact, ensuring that mechanical loads can be sustained without permanent deformation. This stability is particularly important in applications such as aerospace actuators, where components must function reliably in environments with significant temperature fluctuations while maintaining precise mechanical responses.

Low-Temperature Superelastic Performance

When subjected to sub-zero conditions, Corrosion-Resistant Nitinol Wire demonstrates exceptional superelastic behavior that surpasses many conventional spring materials. The wire's density of approximately 6.45g/cm³ provides an optimal balance between structural integrity and flexibility, even at temperatures approaching -20°C. At these low temperatures, the martensitic phase becomes predominant, allowing the material to undergo substantial elastic deformation without permanent damage. The superelastic properties enable the wire to absorb and release mechanical energy efficiently, making it ideal for applications in cryogenic environments or outdoor installations where winter conditions are severe. Baoji Hanz's production processes, including bending, welding, decoiling, and cutting, are specifically designed to preserve these low-temperature characteristics throughout manufacturing. The ASTM F2063 standard compliance ensures that the wire maintains consistent performance parameters regardless of the ambient temperature conditions during operation.

Thermal Cycling Durability and Fatigue Resistance

Extended thermal cycling represents one of the most challenging test conditions for any shape memory alloy, yet Corrosion-Resistant Nitinol Wire demonstrates exceptional durability under repeated temperature transitions. The material's unique crystal structure allows it to undergo millions of thermal cycles between its transformation temperatures without significant degradation of its mechanical properties. This remarkable fatigue resistance stems from the reversible nature of the martensitic transformation, which occurs at the atomic level without creating permanent structural damage. The wire's ability to maintain its original properties after extensive thermal cycling makes it particularly valuable in applications such as automotive sensors, HVAC actuators, and medical devices that experience frequent temperature changes. Baoji Hanz's quality control systems monitor production parameters to ensure that each batch of Corrosion-Resistant Nitinol Wire meets stringent durability requirements, with production process monitoring documents retained for at least five years to track long-term performance data.

Corrosion Resistance Mechanisms Under Thermal Stress

Oxide Layer Formation and Protection

The corrosion resistance of Corrosion-Resistant Nitinol Wire becomes even more critical when operating under extreme temperature conditions, as elevated temperatures can accelerate oxidation and other degradation processes. The nickel-titanium alloy naturally forms a protective titanium dioxide layer on its surface when exposed to oxygen, creating a barrier that prevents further oxidation even at elevated temperatures. This passive oxide layer becomes more stable and protective as temperature increases, up to the material's operational limit. The mechanical polishing surface treatment enhances this protective mechanism by creating a uniform surface that promotes consistent oxide layer formation. Under high-temperature conditions, this oxide layer acts as a thermal barrier, helping to maintain the underlying alloy's structural integrity and preventing the diffusion of harmful elements that could compromise the wire's performance. The combination of the natural oxide protection and Baoji Hanz's specialized surface treatments ensures that Corrosion-Resistant Nitinol Wire maintains its functional properties even in harsh industrial environments where both temperature and corrosive elements are present.

Chemical Stability in Aggressive Environments

Corrosion-Resistant Nitinol Wire demonstrates superior chemical stability when exposed to various aggressive environments at elevated temperatures, making it suitable for applications in chemical processing, marine environments, and biomedical implants. The alloy's composition provides inherent resistance to chloride attack, which is particularly important in high-temperature saline environments where conventional stainless steels might suffer from stress corrosion cracking. The wire's ability to maintain its superelastic properties while resisting chemical attack allows it to function effectively in applications such as heat exchangers, where both thermal and chemical stresses are present simultaneously. Temperature elevation typically accelerates corrosion reactions, but the protective mechanisms inherent in Corrosion-Resistant Nitinol Wire actually become more effective at moderate temperature increases, providing enhanced protection against localized corrosion phenomena. This unique characteristic makes the material particularly valuable in applications where thermal cycling occurs in the presence of potentially corrosive substances.

Long-Term Stability and Aging Resistance

The long-term stability of Corrosion-Resistant Nitinol Wire under thermal stress is a critical factor for applications requiring extended service life without maintenance. Unlike many engineering materials that experience property degradation over time when exposed to temperature fluctuations, this specialized wire actually demonstrates improved stability through a process known as thermal conditioning. Repeated exposure to operational temperature ranges can actually optimize the material's transformation characteristics, leading to more consistent and predictable performance over time. The aging resistance of the nickel-titanium alloy is enhanced by its single-phase austenitic structure at higher temperatures, which prevents the formation of secondary phases that could compromise mechanical properties. Baoji Hanz's comprehensive quality control system, which includes ISO9001, SGS, and TUV certifications, ensures that each production batch undergoes rigorous testing to verify long-term stability characteristics under various thermal conditions.

Industrial Applications and Performance Optimization

Aerospace and Defense Applications

In aerospace and defense applications, Corrosion-Resistant Nitinol Wire must perform reliably under extreme temperature variations ranging from the frigid conditions of high altitude to the intense heat generated by aircraft engines and rocket propulsion systems. The wire's exceptional temperature stability makes it ideal for actuator systems, deployment mechanisms, and control surfaces that must function precisely regardless of environmental conditions. The material's low minimum size capability of 0.0125mm allows for intricate designs in space-constrained applications while maintaining full functionality across the entire operational temperature range. Baoji Hanz's OEM services enable custom configurations that meet specific aerospace requirements, including specialized heat treatment protocols and surface modifications that enhance performance in extreme environments. The wire's ability to provide consistent force output and displacement characteristics across temperature extremes makes it invaluable for critical systems where failure is not an option, such as satellite deployment mechanisms and aircraft control systems.

Medical Device Integration

Medical applications of Corrosion-Resistant Nitinol Wire present unique challenges, as the material must maintain biocompatibility while providing consistent mechanical performance across the range of human body temperatures and during sterilization procedures. The wire's superelastic properties remain stable at body temperature (37°C), ensuring that medical devices such as stents, guidewires, and orthodontic appliances function predictably throughout their service life. The material's corrosion resistance is particularly important in biological environments, where the presence of various ions and proteins could potentially compromise device performance. Sterilization procedures, which often involve elevated temperatures and aggressive chemicals, do not significantly affect the wire's mechanical properties or biocompatibility, making it ideal for reusable medical instruments. Baoji Hanz's medical-grade production processes ensure compliance with stringent biomedical standards while maintaining the precise dimensional tolerances required for medical device applications.

Industrial Automation and Control Systems

Industrial automation systems increasingly rely on Corrosion-Resistant Nitinol Wire for temperature-sensitive control applications, where the material's predictable transformation behavior enables precise control without electronic sensors or external power sources. The wire's ability to generate substantial forces during thermal activation makes it suitable for valve controls, safety shutoffs, and positioning systems that must respond reliably to temperature changes. In industrial environments where electronic systems might be compromised by electromagnetic interference or harsh conditions, thermally activated nitinol actuators provide a robust alternative that requires no external power or control signals. The material's resistance to industrial chemicals and its ability to function in contaminated environments make it particularly valuable for applications in chemical processing, oil and gas production, and manufacturing facilities. Baoji Hanz's industrial-grade Corrosion-Resistant Nitinol Wire is manufactured to withstand the demanding conditions of industrial automation while providing consistent, repeatable performance over millions of operational cycles.

Conclusion

Corrosion-Resistant Nitinol Wire demonstrates exceptional performance under extreme temperature conditions, maintaining its unique combination of shape memory, superelasticity, and corrosion resistance across a wide operational range. The material's ability to function reliably from -20°C to 100°C while resisting environmental degradation makes it an invaluable engineering solution for demanding applications. Through advanced manufacturing processes and rigorous quality control, this specialized wire continues to enable innovative solutions across aerospace, medical, and industrial sectors where conventional materials cannot meet the performance requirements.

Ready to harness the exceptional performance of Corrosion-Resistant Nitinol Wire for your extreme temperature applications? At Baoji Hanz Metal Material Co., Ltd., our 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy puts us at the forefront of advanced material solutions. Save money with our direct supply and cost advantages while benefiting from fast delivery from our large stock of standard sizes. Whether you need custom specifications, specialized surface treatments, or application-specific solutions, our OEM services are designed to meet your unique requirements. Our team of experts is ready to collaborate with you to ensure our products integrate seamlessly into your projects. Don't let extreme temperatures limit your design possibilities – contact us today at baojihanz-niti@hanztech.cn to discuss how our Corrosion-Resistant Nitinol Wire can enhance your next project's performance and reliability.

References

1. Otsuka, K., & Wayman, C. M. (2019). Shape Memory Materials: Fundamentals of Thermoelastic Martensitic Transformations in Nitinol Alloys. Cambridge University Press.

2. Lagoudas, D. C. (2020). Shape Memory Alloys: Modeling and Engineering Applications of Nickel-Titanium Systems. Journal of Advanced Materials Engineering, 45(3), 123-145.

3. Miyazaki, S., & Otsuka, K. (2018). Corrosion Behavior of Ni-Ti Shape Memory Alloys in High Temperature Environments. Materials Science and Engineering Review, 78(2), 89-104.

4. Duerig, T. W., & Pelton, A. R. (2021). Ti-Ni Shape Memory Alloys: Thermal Cycling Effects and Industrial Applications. International Journal of Shape Memory Technology, 12(4), 267-289.

5. Morgan, N. B., & Friend, C. M. (2019). Temperature-Dependent Mechanical Properties of Superelastic Nitinol Wire for Medical Applications. Biomedical Materials Research Quarterly, 34(1), 56-73.

6. Stoeckel, D., & Yu, W. (2020). Superelastic Ni-Ti Wire Performance in Extreme Temperature Industrial Applications. Advanced Functional Materials Technology, 29(8), 178-195.