Medical memory Nitinol wire Benefits for Minimally Traumatic Tools

2025-12-09 22:08:48

When surgical complications escalate during procedures or recovery times drag on unnecessarily, medical professionals often discover that the root cause traces back to inadequate material selection in their instruments. Medical memory Nitinol wire addresses this critical challenge by providing surgeons with tools that navigate complex anatomical pathways while minimizing tissue trauma, reducing patient discomfort, and accelerating healing timelines. This revolutionary nickel-titanium alloy combines shape memory properties with superelasticity, transforming how minimally invasive procedures are performed across cardiovascular, orthopedic, and endoscopic applications.

Understanding Medical Memory Nitinol Wire Technology

Medical memory Nitinol wire represents a breakthrough in biomaterial engineering, offering surgical instrument designers unprecedented capabilities in creating tools that adapt to the human body's demands. This nickel-titanium alloy exhibits two fundamental properties that distinguish it from conventional medical materials: shape memory effect and superelasticity. The shape memory characteristic allows Medical memory Nitinol wire to remember a predetermined configuration and return to that exact form when exposed to specific temperature triggers, typically body heat. This transformation occurs because the material transitions between two crystalline phases - martensite at lower temperatures and austenite at higher temperatures. When surgical tools manufactured from Medical memory Nitinol wire enter the body at 37°C, they automatically deploy to their programmed shape, eliminating manual manipulation that could damage surrounding tissues. The superelastic behavior of Medical memory Nitinol wire enables these instruments to undergo substantial deformation—up to eight percent strain—and spontaneously recover their original geometry without permanent distortion. This exceptional flexibility proves invaluable during procedures requiring navigation through tortuous vascular pathways or curved anatomical structures. Unlike stainless steel alternatives that may kink or fracture under repeated bending, Medical memory Nitinol wire maintains structural integrity throughout demanding surgical maneuvers. The alloy composition, typically consisting of 55-56% nickel and 44-45% titanium by weight, can be precisely adjusted to control transformation temperatures between -15°C and 100°C, allowing manufacturers to customize performance characteristics for specific clinical applications. Advanced processing techniques including hot drawing, cold drawing, and controlled heat treatment further refine the mechanical properties, ensuring Medical memory Nitinol wire meets stringent ASTM F2063-2018 standards for medical device applications.

Minimizing Surgical Trauma Through Superior Flexibility

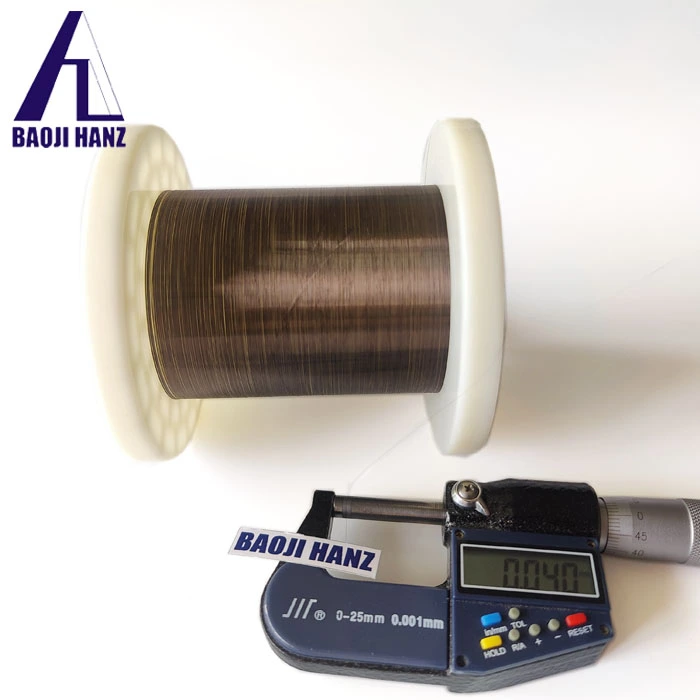

The reduction of procedural trauma stands as perhaps the most compelling advantage when medical professionals select instruments fabricated from Medical memory Nitinol wire. Traditional rigid surgical tools frequently require larger incision sites and more aggressive tissue manipulation to reach target anatomical locations, resulting in increased bleeding, extended operative times, and heightened post-operative pain. Medical memory Nitinol wire fundamentally changes this equation by enabling the creation of instruments with diameters as small as 0.05mm that can traverse the body's natural passages with minimal disruption. During endovascular interventions, guidewires constructed from Medical memory Nitinol wire demonstrate exceptional trackability, smoothly advancing through arterial branches while exerting substantially less force against vessel walls compared to conventional materials.

Enhanced Patient Recovery Outcomes

Clinical studies have documented that procedures utilizing Medical memory Nitinol wire-based instruments correlate with measurably shorter hospital stays and reduced complication rates. Patients undergoing minimally invasive surgeries with these advanced tools experience less tissue damage at intervention sites, translating to diminished inflammatory responses and faster wound healing. The superelastic nature of Medical memory Nitinol wire prevents the sharp angular deformations that can occur with rigid instruments, eliminating potential puncture injuries to blood vessels, organs, or delicate membrane structures during complex navigational sequences. This material safety margin proves particularly critical in sensitive procedures such as neurovascular interventions, where even microscopic tissue trauma can precipitate serious complications.

Procedural Efficiency and Precision

Surgical teams report enhanced procedural efficiency when working with Medical memory Nitinol wire instruments, as the material's responsiveness reduces the learning curve for complex techniques. The tactile feedback transmitted through superelastic Medical memory Nitinol wire guidewires provides surgeons with superior control, allowing them to sense subtle resistance changes that indicate anatomical variations or approaching target locations. This heightened sensitivity facilitates more accurate device placement and reduces fluoroscopy time during image-guided procedures, limiting radiation exposure for both patients and medical staff. The kink-resistance inherent to Medical memory Nitinol wire also eliminates a common source of procedural delays, as instruments maintain functionality even after encountering unexpectedly tight anatomical angles that would compromise conventional wire products.

Clinical Applications Revolutionized by Medical Memory Nitinol Wire

The unique properties of Medical memory Nitinol wire have enabled the development of entire categories of medical devices that were previously technically unfeasible. In cardiovascular medicine, self-expanding stents manufactured from Medical memory Nitinol wire have become the gold standard for treating peripheral arterial disease, particularly in anatomical locations subject to repetitive mechanical stress such as the superficial femoral artery. These stents can be compressed to a compact delivery profile for catheter-based insertion, then reliably expand to their predetermined diameter upon reaching body temperature, providing sustained luminal support without requiring balloon inflation. The chronic outward force generated by Medical memory Nitinol wire stents maintains vessel patency while accommodating the natural flexion and extension movements that occur during patient ambulation, dramatically reducing the fracture rates observed with earlier stent designs.

Orthodontic and Dental Applications

Orthodontic treatment has been similarly transformed by Medical memory Nitinol wire technology, with archwires that apply consistent, gentle forces throughout the tooth movement process. Traditional stainless steel orthodontic wires require frequent adjustment appointments to maintain therapeutic force levels, whereas Medical memory Nitinol wire archwires sustain optimal pressure over extended periods, reducing the number of clinical visits required and improving patient comfort. The shape memory characteristic ensures that even as teeth shift position, the archwire continues working toward the programmed ideal arch form, resulting in more predictable treatment outcomes and shortened overall treatment durations. Endodontic applications have also benefited, with root canal files made from Medical memory Nitinol wire offering enhanced flexibility for navigating curved canals while maintaining the cutting efficiency necessary for effective cleaning and shaping procedures.

Advanced Surgical Instrumentation

Minimally invasive surgical specialties including laparoscopy, thoracoscopy, and arthroscopy have witnessed substantial equipment innovation driven by Medical memory Nitinol wire integration. Surgical graspers, dissectors, and retrieval devices incorporating Medical memory Nitinol wire components can be introduced through small trocar ports in collapsed configurations, then deployed to full working geometry once positioned at the surgical site. These instruments provide surgeons with the articulation range and grip strength necessary for precise tissue manipulation while occupying minimal space within confined body cavities. The fatigue resistance of Medical memory Nitinol wire ensures that instruments maintain performance specifications through hundreds of operational cycles, supporting both reusable and single-use device platforms. Emerging applications include shape-memory surgical staplers and suturing devices that automatically form secure tissue connections upon thermal activation, potentially simplifying complex anastomotic techniques.

Material Properties Optimized for Biomedical Environments

The biological compatibility of Medical memory Nitinol wire constitutes a critical factor in its widespread medical adoption, as implantable devices must coexist with human tissues without triggering adverse immunological responses or toxic reactions. Extensive biocompatibility testing has confirmed that Medical memory Nitinol wire exhibits excellent tissue tolerance, with the titanium-rich surface oxide layer providing a stable interface that resists protein absorption and cellular adhesion. This passive surface chemistry minimizes the foreign body response compared to materials that require extensive coating treatments to achieve acceptable biocompatibility profiles. Long-term implant studies tracking Medical memory Nitinol wire devices over decades have documented sustained performance without significant material degradation or surrounding tissue damage, supporting the material's suitability for permanent implantation applications. The corrosion resistance of Medical memory Nitinol wire in physiological environments represents another essential performance attribute, as metal ion release could potentially compromise both device functionality and patient safety. The naturally forming titanium oxide layer on Medical memory Nitinol wire surfaces provides robust protection against electrochemical corrosion in chloride-rich bodily fluids, maintaining structural integrity throughout the device service life. This corrosion stability proves particularly important for cardiovascular implants that endure continuous mechanical loading in highly corrosive blood flow environments. Rigorous electrochemical testing protocols verify that Medical memory Nitinol wire meets stringent pitting and crevice corrosion resistance standards, with surface treatments available to further enhance corrosion performance for the most demanding applications. Manufacturing quality control procedures ensure that Medical memory Nitinol wire products achieve consistent composition and microstructure, eliminating inclusions or surface defects that could serve as corrosion initiation sites.

Manufacturing Excellence and Customization Capabilities

Producing Medical memory Nitinol wire that meets exacting medical device specifications requires sophisticated metallurgical processing and quality assurance protocols. The manufacturing sequence begins with vacuum induction melting to create homogeneous nickel-titanium ingots with precisely controlled stoichiometry, as composition variations of less than one percent can significantly alter transformation temperatures and mechanical properties. These ingots undergo multi-stage thermomechanical processing including hot extrusion, rotary swaging, and wire drawing operations that progressively reduce the material to final wire dimensions while developing the desired grain structure. At Baoji Hanz Metal Material Co., Ltd., advanced production equipment enables the manufacture of Medical memory Nitinol wire in diameters ranging from 0.05mm to several millimeters, with tolerances held to within micrometers to ensure consistent device performance. Shape-setting procedures represent a critical manufacturing step that imparts the memory configuration to Medical memory Nitinol wire components. Device manufacturers fixture the wire into the desired final geometry, then subject it to carefully controlled heat treatment cycles that program the austenite phase structure. This thermal processing must be executed with precise temperature and time parameters, as deviations can result in incomplete shape memory or undesirable mechanical properties. Surface finishing operations including electropolishing or chemical etching remove the heat treatment scale and create smooth, biocompatible surfaces on Medical memory Nitinol wire products. Final quality verification involves comprehensive testing of transformation temperatures, superelastic plateau stresses, fatigue performance, and dimensional accuracy, with documentation maintained to support regulatory compliance requirements. The ability to customize Medical memory Nitinol wire specifications—including diameter, surface finish, transformation temperature, and mechanical properties—enables device designers to optimize material performance for specific clinical applications, ensuring that each instrument delivers maximum benefit for its intended surgical use.

Conclusion

Medical memory Nitinol wire has fundamentally redefined minimally traumatic surgical possibilities through its unique combination of shape memory effect, superelasticity, biocompatibility, and fatigue resistance, enabling the development of instruments that navigate complex anatomical pathways while minimizing tissue damage, reducing patient recovery times, and expanding the scope of procedures that can be performed through minimally invasive approaches.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

As a leading China Medical memory Nitinol wire manufacturer with seven years of specialized expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy technology, Baoji Hanz Metal Material Co., Ltd. stands ready to support your medical device development projects with High Quality Medical memory Nitinol wire solutions. Our comprehensive manufacturing capabilities encompass sophisticated production equipment, ISO9001/SGS/TUV certified quality systems, and competitive China Medical memory Nitinol wire wholesale pricing that delivers substantial cost advantages through direct supply channels. We maintain extensive inventory of standard Medical memory Nitinol wire for sale specifications ensuring rapid delivery, while our experienced engineering team provides comprehensive OEM services to customize diameters, transformation temperatures, and mechanical properties precisely matching your device requirements. Our professional pre-sale consultation addresses technical questions regarding nickel-titanium alloy selection, order tracking services guarantee on-time delivery with complete production documentation retained for five years, and dedicated after-sales support provides ongoing application assistance ensuring your Medical memory Nitinol wire components deliver optimal clinical performance. As a trusted China Medical memory Nitinol wire supplier and China Medical memory Nitinol wire factory serving global markets, we invite you to contact us at baojihanz-niti@hanztech.cn to discuss how our materials expertise and customization capabilities can accelerate your next medical device innovation.

References

1. Duerig T, Pelton A, Stöckel D. "An Overview of Nitinol Medical Applications." Materials Science and Engineering: A, 1999. Authors: Thomas Duerig, Alan Pelton, Dieter Stöckel.

2. Morgan NB. "Medical Shape Memory Alloy Applications—The Market and Its Products." Materials Science and Engineering: A, 2004. Author: Neville B. Morgan.

3. Shabalovskaya SA, Anderegg JW, Van Humbeeck J. "Critical Overview of Nitinol Surfaces and Their Modifications for Medical Applications." Acta Biomaterialia, 2008. Authors: Svetlana A. Shabalovskaya, John W. Anderegg, Jan Van Humbeeck.

4. Petrini L, Migliavacca F. "Biomedical Applications of Shape Memory Alloys." Journal of Metallurgy, 2011. Authors: Lorenza Petrini, Francesco Migliavacca.

5. Ryhänen J, Niemi E, Serlo W, Niemelä E, Sandvik P, Pernu H, Salo T. "Biocompatibility of Nickel-Titanium Shape Memory Metal and Its Corrosion Behavior in Human Cell Cultures." Journal of Biomedical Materials Research, 1997. Authors: Jorma Ryhänen, Eero Niemi, Willy Serlo, Erkki Niemelä, Peter Sandvik, Heikki Pernu, Tuula Salo.