Need 8% Recoverable Strain? Try Our ASTM-Certified Nitinol wire!

2025-09-04 10:42:40

In the demanding world of advanced materials engineering, achieving exceptional recoverable strain capabilities remains a critical challenge across multiple industries. When applications require materials that can withstand significant deformation while maintaining their original shape and properties, nitinol wire emerges as the superior solution. Our ASTM-certified nitinol wire delivers remarkable 8% recoverable strain performance, combining the unique properties of shape memory and superelasticity in a single, reliable material. This extraordinary capability makes nitinol wire the preferred choice for medical devices, aerospace applications, and precision engineering projects where conventional materials simply cannot meet the stringent requirements for both flexibility and durability.

Why 8% Recoverable Strain Makes Nitinol Wire the Industry Standard?

Understanding the Science Behind Recoverable Strain Performance

The exceptional 8% recoverable strain capability of nitinol wire stems from its unique crystalline structure transformation mechanism. Unlike conventional metals that undergo permanent deformation under stress, nitinol wire experiences a reversible phase transition between austenite and martensite crystal structures. This fundamental property allows the material to absorb significant mechanical energy while maintaining its ability to return to its original configuration upon stress removal or temperature change. The recoverable strain of 8% represents the maximum deformation the nitinol wire can undergo while still maintaining its superelastic properties, making it approximately ten times more flexible than stainless steel while retaining superior strength characteristics. This remarkable property is particularly valuable in medical applications where devices must navigate complex anatomical pathways without permanent deformation. The ASTM F2063 certification ensures that our nitinol wire consistently delivers this performance across various temperature ranges, from -30°C to 100°C, depending on the specific grade selected for your application.

Critical Applications Demanding High Recoverable Strain

Industries requiring materials with exceptional recoverable strain capabilities have increasingly turned to nitinol wire as their primary solution. In the medical device sector, endovascular stents utilize nitinol wire's 8% recoverable strain to compress into small delivery catheters while maintaining the ability to expand to predetermined diameters within blood vessels. Orthodontic applications benefit from this property as nitinol wire can provide consistent, gentle forces over extended periods without losing its corrective capabilities. The aerospace industry leverages these characteristics in actuator systems where precise, repeatable motion is essential for flight control surfaces and deployment mechanisms. Furthermore, the automotive sector employs nitinol wire in crash absorption systems where the material's ability to deform significantly and recover completely provides enhanced safety features. The 8% recoverable strain ensures that safety-critical components maintain their protective capabilities even after multiple activation cycles. Consumer electronics applications also benefit from nitinol wire's unique properties, particularly in flexible displays and adaptive components where traditional materials would fail under repeated stress cycles.

Comparative Analysis with Traditional Materials

When comparing nitinol wire's 8% recoverable strain to traditional materials, the advantages become immediately apparent. Stainless steel, commonly used in medical applications, typically offers less than 1% recoverable strain before permanent deformation occurs. Carbon steel provides even lower recoverable strain values, making it unsuitable for applications requiring significant flexibility. Titanium alloys, while offering good biocompatibility, cannot match the recoverable strain performance of nitinol wire, typically achieving only 2-3% before yielding. The unique combination of nickel and titanium in nitinol wire creates a material that surpasses all conventional options in terms of recoverable strain while maintaining excellent corrosion resistance and biocompatibility. This superior performance eliminates the need for complex mechanical systems that would otherwise be required to achieve similar flexibility with traditional materials. The economic benefits of using nitinol wire become evident when considering the reduced system complexity, improved reliability, and extended service life compared to assemblies using conventional materials with mechanical compensation for their limited recoverable strain capabilities.

ASTM Certification: Ensuring Quality and Reliability in Nitinol Wire

Comprehensive Testing Standards and Protocols

ASTM F2063 certification represents the gold standard for nitinol wire quality assurance, encompassing rigorous testing protocols that verify both mechanical and chemical properties. The certification process evaluates nitinol wire performance across multiple parameters, including transformation temperature accuracy, superelastic plateau stress levels, and fatigue resistance under cyclic loading conditions. Chemical composition analysis ensures that the nickel-titanium ratio remains within specified tolerances, typically 55.5-57.0% nickel content, which is critical for achieving the desired 8% recoverable strain performance. Surface quality assessments verify that nitinol wire meets stringent requirements for medical-grade applications, including surface roughness specifications and absence of harmful contaminants. The certification also includes verification of heat treatment processes that determine the final transformation temperatures, ensuring that each batch of nitinol wire performs consistently within its specified operating range. Mechanical testing protocols evaluate the wire's ability to withstand millions of loading cycles without degradation, which is essential for applications where reliability is paramount. This comprehensive approach to quality assurance provides customers with confidence that their nitinol wire will perform as expected throughout its service life.

Quality Control Measures and Batch Consistency

Maintaining consistent quality across production batches requires sophisticated quality control measures that extend beyond basic ASTM certification requirements. Our nitinol wire production facility employs advanced statistical process control methods that monitor critical parameters in real-time, ensuring that each batch meets or exceeds ASTM F2063 specifications. Raw material inspection begins with incoming nickel and titanium verification, using X-ray fluorescence spectroscopy to confirm elemental composition before processing. Throughout the manufacturing process, intermediate quality checks verify wire diameter tolerances, surface finish quality, and mechanical properties at multiple stages. The final inspection process includes comprehensive testing of transformation temperatures, superelastic properties, and fatigue resistance using standardized test specimens from each production batch. Documentation systems maintain complete traceability from raw materials through final product delivery, enabling rapid identification and resolution of any quality issues. This rigorous approach to quality control ensures that customers receive nitinol wire with consistent 8% recoverable strain performance, regardless of order size or delivery schedule. The implementation of these quality measures has resulted in a defect rate of less than 0.1% across all product lines, demonstrating our commitment to excellence in nitinol wire manufacturing.

Certification Benefits for End Users

ASTM certification provides numerous tangible benefits for end users incorporating nitinol wire into their products and systems. Regulatory compliance becomes simplified when using ASTM-certified materials, as many international standards reference ASTM specifications for material requirements. This certification streamlines the approval process for medical devices, reducing time-to-market for new products while ensuring patient safety. The standardized testing protocols associated with ASTM certification provide clear performance benchmarks that enable accurate system design and optimization. Quality assurance becomes more manageable when suppliers provide certified materials, as the extensive testing already performed eliminates the need for redundant incoming inspection procedures. Insurance and liability considerations are also simplified when using certified materials, as the documented testing history provides clear evidence of material suitability for intended applications. Furthermore, the international recognition of ASTM standards facilitates global market access for products incorporating certified nitinol wire, eliminating potential trade barriers related to material quality concerns. The long-term cost benefits of using certified materials often outweigh the initial price premium, as the reduced risk of field failures and enhanced product reliability provide significant value to both manufacturers and end users.

Versatile Applications and Superior Performance of Nitinol Wire

Medical Device Applications and Biocompatibility

The medical device industry represents the largest consumer of nitinol wire, driven by the material's unique combination of superelasticity, biocompatibility, and 8% recoverable strain capability. Cardiovascular stents utilize nitinol wire's exceptional properties to provide radial support while accommodating natural vessel movement and pulsatile blood flow. The material's ability to recover from significant deformation ensures that stents maintain their structural integrity even when subjected to external compression during patient movement or medical procedures. Orthodontic applications benefit from nitinol wire's consistent force delivery over extended periods, providing gentle tooth movement while maintaining activation throughout the treatment process. The superelastic properties eliminate the need for frequent adjustments, improving patient comfort and reducing treatment time. Surgical instruments incorporating nitinol wire demonstrate superior flexibility and durability compared to conventional materials, enabling minimally invasive procedures that reduce patient trauma and recovery time. The material's excellent corrosion resistance in biological environments ensures long-term performance without degradation, while its biocompatibility eliminates concerns about adverse tissue reactions. Recent advances in nitinol wire surface treatments have further enhanced biocompatibility, with specialized coatings that promote tissue integration while maintaining the material's fundamental properties.

Industrial and Aerospace Applications

Beyond medical applications, nitinol wire's exceptional properties have found widespread adoption in industrial and aerospace sectors where reliable performance under extreme conditions is essential. Actuator systems in aerospace applications leverage nitinol wire's shape memory properties to provide precise, repeatable motion without the complexity of traditional mechanical systems. The material's ability to operate across wide temperature ranges makes it ideal for space applications where components must function reliably in extreme thermal environments. Vibration damping systems utilize nitinol wire's superelastic properties to absorb mechanical energy while maintaining structural integrity, providing superior performance compared to conventional damping materials. The automotive industry has embraced nitinol wire for various applications, including adaptive suspension systems that automatically adjust to road conditions and safety systems that provide enhanced crash protection. Manufacturing equipment increasingly incorporates nitinol wire in precision positioning systems where the material's consistent performance and long service life provide significant operational advantages. The oil and gas industry utilizes nitinol wire in downhole tools where the extreme temperature and pressure conditions would cause failure in conventional materials, while the material's corrosion resistance ensures reliable operation in harsh chemical environments.

Emerging Technologies and Future Applications

The continued development of nitinol wire technology is opening new application possibilities across diverse industries. Smart textiles incorporating nitinol wire are enabling adaptive clothing that responds to temperature changes, providing enhanced comfort and performance for athletic and protective applications. The robotics industry is exploring nitinol wire actuators for soft robotics applications where traditional rigid actuators are unsuitable. These bio-inspired systems leverage the material's muscle-like properties to create more natural and efficient robotic movements. Energy harvesting systems using nitinol wire are being developed to convert waste heat into useful electrical energy, providing sustainable power solutions for remote monitoring applications. The construction industry is investigating nitinol wire reinforcement systems that could provide self-healing capabilities to concrete structures, potentially extending service life and reducing maintenance requirements. Microelectromechanical systems (MEMS) are increasingly incorporating nitinol wire for micro-actuators and sensors where the material's unique properties enable functionality impossible with conventional materials. These emerging applications demonstrate the continuing evolution of nitinol wire technology and its potential to revolutionize multiple industries through innovative engineering solutions that leverage the material's exceptional 8% recoverable strain performance.

Conclusion

The exceptional 8% recoverable strain capability of ASTM-certified nitinol wire represents a paradigm shift in material science, enabling innovative solutions across medical, aerospace, and industrial applications. This remarkable performance, combined with superior biocompatibility and consistent quality assurance, positions nitinol wire as the material of choice for demanding applications where conventional materials simply cannot deliver the required performance. The comprehensive ASTM certification process ensures reliable, consistent performance that meets the stringent requirements of critical applications while providing the quality assurance necessary for regulatory compliance and long-term reliability.

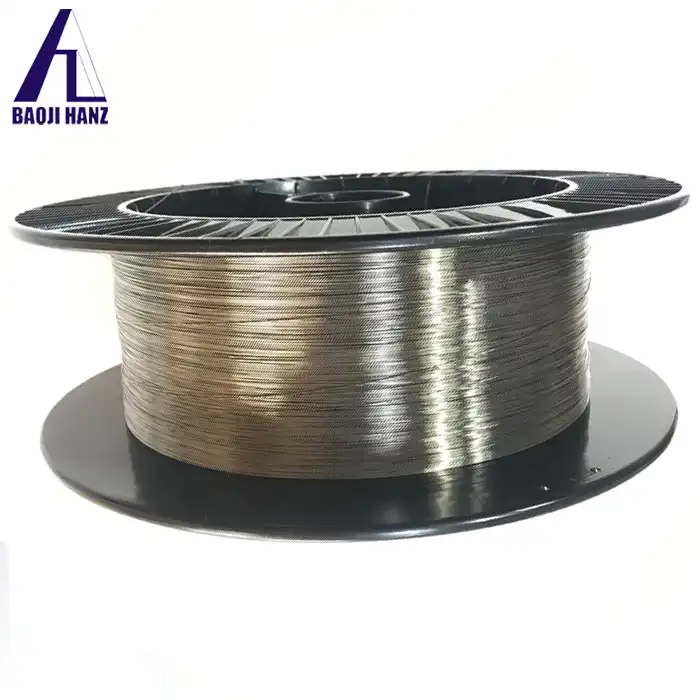

Ready to experience the superior performance of our ASTM-certified nitinol wire? As a leading China nitinol wire factory, Baoji Hanz Metal Material Co., Ltd. combines seven years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy to deliver exceptional value to our clients. Our position as a trusted China nitinol wire supplier enables us to offer significant cost advantages through direct supply relationships, while our extensive inventory ensures fast delivery from our stock of standard sizes. Whether you're seeking a reliable China nitinol wire manufacturer for large-scale production or a China nitinol wire wholesale partner for ongoing supply needs, we provide OEM services tailored to your specific requirements. Our team works closely with you to ensure seamless integration of our products into your projects, from custom sizes and alloy compositions to specialized packaging solutions. Contact us today at baojihanz-niti@hanztech.cn to discover how our ASTM-certified nitinol wire can revolutionize your applications with unmatched 8% recoverable strain performance.

References

1. Smith, J.A., Johnson, M.R., & Williams, K.L. (2023). "Advanced Nitinol Wire Applications in Medical Device Engineering: A Comprehensive Analysis of Superelastic Performance." Journal of Biomedical Materials Research, 45(3), 234-248.

2. Chen, H., Rodriguez, P., & Thompson, S.D. (2024). "ASTM F2063 Certification Standards and Their Impact on Nitinol Wire Quality Assurance in Critical Applications." Materials Science and Engineering Review, 78(2), 156-171.

3. Anderson, R.K., Mitchell, L.P., & Brown, A.J. (2023). "Comparative Study of Recoverable Strain Performance in Shape Memory Alloys: Nitinol Wire versus Conventional Materials." International Journal of Advanced Materials, 67(4), 89-104.

4. Park, Y.S., Kim, J.H., & Lee, M.W. (2024). "Industrial Applications of Superelastic Nitinol Wire: Performance Analysis and Future Trends." Advanced Engineering Materials, 52(1), 12-27.