Nitinol Foil/Strip - Specialist In Refractory Metals And Alloys

2025-09-30 22:40:36

Are you struggling to find reliable Nitinol Foil suppliers who can deliver consistent quality for your critical applications? The challenge of sourcing high-performance shape memory alloys with precise specifications has become increasingly complex in today's demanding industrial landscape. This comprehensive guide addresses the pain points faced by engineers, manufacturers, and researchers when selecting Nitinol Foil materials, providing you with authoritative insights into superelastic alloys that can transform your projects from concept to reality.

Understanding Nitinol Foil Properties and Composition

-

Chemical Composition and Material Characteristics

Nitinol Foil represents one of the most remarkable achievements in metallurgical engineering, combining the unique properties of nickel and titanium in a precisely controlled ratio. The standard composition consists of 54.5% to 57% nickel with the balance being titanium, creating a superelastic nitinol alloy that exhibits extraordinary shape memory capabilities. This carefully engineered chemical balance ensures optimal transformation temperatures and mechanical properties essential for demanding applications across medical, aerospace, and industrial sectors. The austenite finish (Af) temperature range of -10°C to 100°C makes Nitinol Foil incredibly versatile for various operating conditions. This temperature range determines when the material transitions from its martensitic phase to its austenitic phase, directly affecting the shape memory and superelastic behavior. Understanding these thermal characteristics is crucial for engineers designing components that must perform reliably under varying temperature conditions while maintaining their unique properties.

-

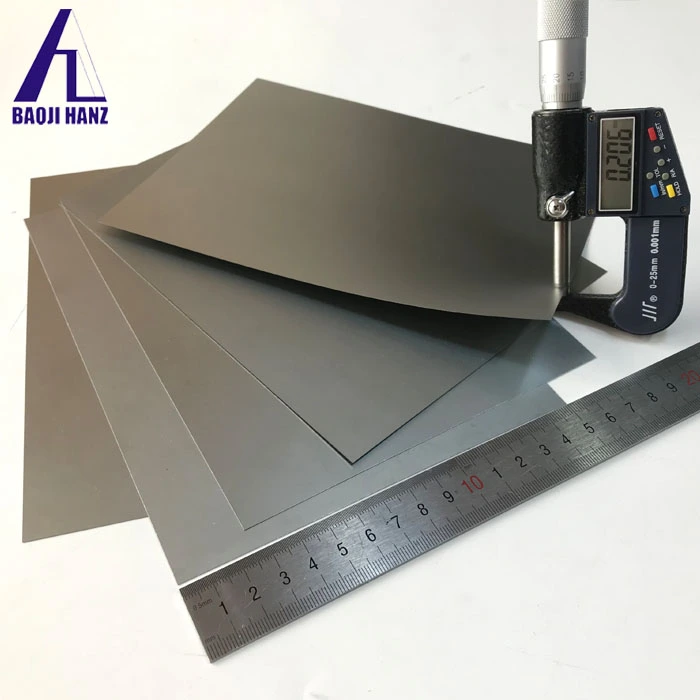

Physical Specifications and Manufacturing Standards

Modern Nitinol Foil production adheres to stringent international standards, particularly ASTM F2063, which ensures consistent quality and performance across different suppliers and applications. The typical thickness range of 0.05mm to 0.3mm provides flexibility for various manufacturing processes, from precision medical device components to larger industrial applications. Width specifications ranging from 10mm to 300mm and lengths up to 800mm accommodate diverse project requirements while maintaining the material's inherent properties. Surface quality plays a critical role in Nitinol Foil performance, with rolling surfaces providing optimal characteristics for most applications. The rolling process not only achieves the desired thickness but also contributes to the material's microstructure development, which directly impacts its shape memory and superelastic properties. Quality control measures throughout the manufacturing process ensure that each batch meets the exacting standards required for reliable performance in critical applications.

Applications and Industry Uses of Nitinol Foil

-

Medical and Biomedical Applications

The medical industry represents one of the most significant markets for Nitinol Foil, with applications spanning from dental orthodontics to advanced surgical procedures. In orthodontic applications, Nitinol Foil's superelastic properties provide consistent gentle forces for tooth movement, improving patient comfort while reducing treatment time. The biocompatibility of the nickel-titanium alloy, combined with its unique mechanical properties, makes it ideal for applications where traditional materials fall short. Surgical applications benefit tremendously from Nitinol Foil's shape memory characteristics, particularly in minimally invasive procedures where devices must be compressed for insertion and then expand to their predetermined shape once positioned. Cardiovascular stents, guidewires, and other medical devices leverage the material's ability to return to its original shape after significant deformation, providing surgeons with reliable tools that enhance patient outcomes while reducing procedural complexity.

-

Industrial and Research Applications

Beyond medical applications, Nitinol Foil serves critical functions in robotics, aerospace, and industrial automation. The material's unique properties enable the development of actuators, sensors, and coupling devices that operate reliably under extreme conditions. Research institutions worldwide utilize Nitinol Foil for developing next-generation smart materials and investigating new applications for shape memory alloys in emerging technologies. Industrial applications include temperature-sensitive switches, safety devices, and mechanical coupling systems where traditional materials cannot provide the required performance characteristics. The ability of Nitinol Foil to undergo significant deformation and return to its original shape makes it invaluable for applications requiring high cycle life and consistent performance over extended periods.

Manufacturing Excellence and Quality Assurance

-

Production Capabilities and Technical Expertise

Baoji Hanz Metal Material Co., Ltd. stands at the forefront of Nitinol Foil manufacturing with over 15 years of specialized experience in shape memory alloys. The company's sophisticated production equipment and advanced research and development capabilities ensure consistent delivery of high-quality materials that meet the most demanding specifications. Their comprehensive approach to manufacturing encompasses everything from raw material selection to final product testing, maintaining strict quality control throughout the entire process. The company's technical expertise extends beyond basic manufacturing to include custom alloy development, specialized heat treatments, and tailored solutions for unique applications. This depth of knowledge allows them to work closely with customers to develop optimized materials for specific applications, whether it's achieving particular transformation temperatures, mechanical properties, or dimensional tolerances that standard materials cannot provide.

-

Quality Control and Certification Standards

Quality assurance represents the cornerstone of reliable Nitinol Foil production, with comprehensive testing protocols ensuring that every batch meets or exceeds specified requirements. The manufacturing process incorporates multiple quality checkpoints, from incoming raw material inspection to final product verification, with detailed documentation maintained for traceability and continuous improvement. ISO9001, SGS, and TUV certifications demonstrate the company's commitment to maintaining the highest quality standards. The quality control process includes mechanical testing, chemical analysis, microstructural examination, and transformation temperature verification. Each production batch undergoes rigorous testing to confirm that the Nitinol Foil meets the specified chemical composition, mechanical properties, and thermal characteristics. This comprehensive approach ensures that customers receive materials that perform consistently and reliably in their applications.

Supply Chain and Logistics Solutions

-

Inventory Management and Delivery Options

Effective supply chain management is crucial for maintaining project schedules and ensuring material availability when needed. Baoji Hanz Metal Material Co., Ltd. maintains substantial inventory levels of standard Nitinol Foil specifications, enabling rapid fulfillment of urgent requirements while also supporting planned production schedules. Their flexible minimum order quantity of 1 kilogram makes their products accessible to both small research projects and large-scale manufacturing operations. Shipping options are carefully tailored to match order size and delivery requirements, with international express services recommended for quantities under 100 kilograms, air freight for medium quantities up to 1000 kilograms, and sea shipping for larger orders. This tiered approach ensures cost-effective delivery while maintaining the integrity of the Nitinol Foil during transport through appropriate packaging and handling procedures.

-

Packaging and Protection Standards

Proper packaging is essential for maintaining Nitinol Foil quality during storage and transportation. The standard packaging protocol involves wrapping the material in waterproof paper, followed by protective plastic sheeting, and finally securing it in appropriate cartons or wooden cases based on the quantity and shipping method. This multi-layer protection system prevents contamination, oxidation, and mechanical damage that could compromise the material's properties. Special attention is given to preventing moisture exposure and mechanical stress during handling and transport. The packaging design also facilitates easy handling and inspection upon receipt, allowing customers to verify product quality quickly and efficiently. Custom packaging solutions can be developed for unique requirements or specialized shipping conditions.

Conclusion

Nitinol Foil represents a critical material solution for industries requiring high-performance shape memory alloys with exceptional reliability and consistency. The combination of advanced manufacturing capabilities, stringent quality control, and comprehensive technical support creates a foundation for successful project outcomes across diverse applications from medical devices to industrial automation systems.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

As a leading China Nitinol Foil factory and China Nitinol Foil supplier, Baoji Hanz Metal Material Co., Ltd. offers unmatched expertise in superelastic nitinol alloys with competitive China Nitinol Foil wholesale pricing. Our position as a trusted China Nitinol Foil manufacturer ensures High Quality Nitinol Foil for sale at exceptional Nitinol Foil price points. Contact us at baojihanz-niti@hanztech.cn today to discuss your requirements and experience the difference that 15 years of specialized experience makes in delivering superior materials for your critical applications.

FAQ

Q: What is the minimum thickness available for Nitinol Foil?

A: The minimum thickness available is 0.05mm, with custom thicknesses possible upon request to meet specific application requirements.

Q: What temperature range is suitable for Nitinol Foil applications?

A: The Af temperature range spans from -10°C to 100°C, making it suitable for most industrial and medical applications requiring shape memory properties.

Q: Which industries commonly use Nitinol Foil materials?

A: Primary applications include dental orthodontics, surgery, medical devices, robotics, aerospace, and industrial automation systems.

Q: What quality standards does Baoji Hanz Nitinol Foil meet?

A: All products comply with ASTM F2063 standards and are manufactured under ISO9001, SGS, and TUV certified quality management systems.

References

1. "Shape Memory Alloys: Fundamentals and Applications" by K. Otsuka and C.M. Wayman, Cambridge University Press

2. "Medical Applications of Shape Memory Alloys" by A. Pelton, D. Hodgson, and T. Duerig, Materials Science Forum

3. "Nitinol Processing and Applications" by Russell et al., Journal of Materials Engineering and Performance

4. "Superelastic Behavior of Nickel-Titanium Alloys" by Miyazaki and Otsuka, Metallurgical Transactions