Nitinol Strip & Nitinol Foil - Special Metal & Machined Parts

2025-09-25 20:26:20

In today's advanced manufacturing landscape, engineers and designers face increasing challenges when traditional materials fail to meet demanding application requirements. Whether you're developing cutting-edge medical devices, aerospace components, or precision industrial equipment, the limitations of conventional metals can become costly bottlenecks in your projects. Nitinol strip and Nitinol foil emerge as revolutionary solutions to these material challenges, offering unique properties that transform impossible designs into reality. This comprehensive guide explores how these special metal and machined parts can solve your most complex engineering problems while delivering exceptional performance and reliability.

Understanding Nitinol Foil Properties and Characteristics

-

Material Composition and Structure

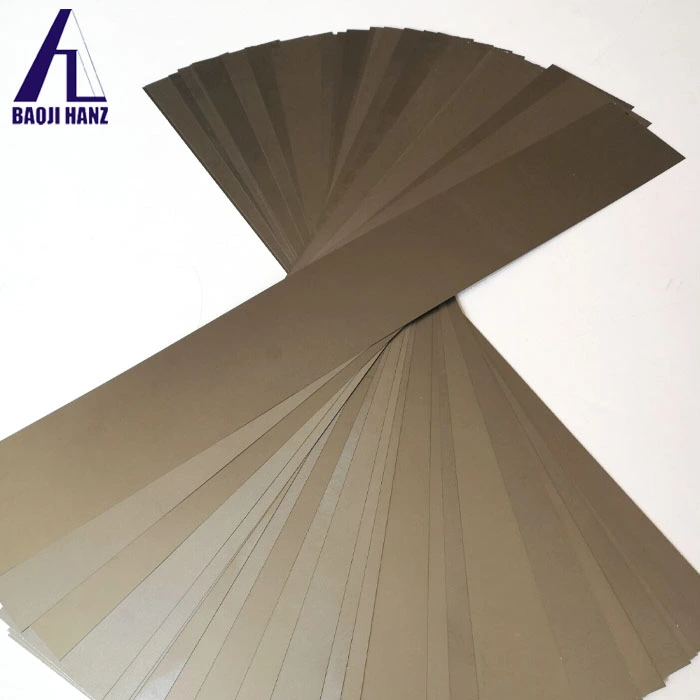

Nitinol foil represents a breakthrough in advanced materials engineering, featuring a precisely controlled composition of 54.5% to 57% nickel with the balance being titanium. This specific chemical composition creates the foundation for its remarkable superelastic properties and shape memory capabilities. The superelastic nitinol material undergoes a unique thermoelastic martensitic phase transformation that enables it to recover from significant deformation without permanent damage. The crystalline structure of Nitinol foil allows for reversible phase transitions between austenite and martensite phases, which directly correlates to its exceptional mechanical properties. The manufacturing process of Nitinol foil requires sophisticated production techniques to achieve the desired thickness range from 0.05mm minimum up to 0.3mm, with custom thicknesses available for specialized applications. The rolling surface treatment ensures consistent mechanical properties across the entire foil width, which can range from 10mm for precision applications to 300mm for larger industrial uses. Temperature control during production is critical, as the Af (austenite finish) temperature range of -10°C to 100°C must be precisely maintained to ensure optimal performance characteristics.

-

Mechanical and Thermal Properties

The extraordinary mechanical properties of Nitinol foil stem from its ability to exhibit both superelasticity and shape memory effects. Superelastic Nitinol foil can withstand strains up to 8% and still return to its original shape upon stress removal, making it ideal for applications requiring repeated loading and unloading cycles. The shape memory effect allows the material to recover its predetermined shape when heated above its transformation temperature, enabling innovative design solutions in temperature-responsive applications. The thermal properties of Nitinol foil are equally impressive, with excellent fatigue resistance and corrosion resistance in various environments. The material maintains its mechanical properties across a wide temperature range, making it suitable for applications in extreme conditions. The unique combination of high strength, excellent flexibility, and biocompatibility positions Nitinol foil as an indispensable material for demanding applications where conventional materials would fail.

Applications and Industries Using Nitinol Strip Materials

-

Medical and Healthcare Applications

The medical industry represents the largest market segment for Nitinol foil and strip materials, driven by their exceptional biocompatibility and unique mechanical properties. In dental orthodontics, Nitinol foil is extensively used in arch wires, brackets, and other orthodontic appliances due to its ability to apply constant, gentle forces throughout the treatment process. The superelastic nature of Nitinol foil ensures that the applied forces remain relatively constant even as teeth move, reducing patient discomfort and improving treatment outcomes. Surgical applications of Nitinol foil include minimally invasive devices such as stents, guidewires, and various implantable devices. The shape memory properties of Nitinol foil enable the creation of self-expanding stents that can be compressed for insertion through small incisions and then expand to their predetermined shape once positioned correctly. This capability has revolutionized cardiovascular surgery, neurosurgery, and other medical specialties by enabling less invasive procedures with improved patient outcomes. The biocompatibility of Nitinol foil, certified under ASTM F2063 standards, ensures safe long-term implantation without adverse tissue reactions. Research applications in the medical field continue to explore new possibilities for Nitinol foil, including drug delivery systems, tissue engineering scaffolds, and advanced diagnostic devices.

-

Industrial and Research Applications

Beyond medical applications, Nitinol foil finds extensive use in industrial applications where its unique properties provide solutions to complex engineering challenges. In the aerospace industry, Nitinol foil is used in actuators, dampers, and various control systems that require precise positioning and reliable operation under extreme conditions. The material's ability to function across wide temperature ranges makes it ideal for space applications where temperature fluctuations are severe. Robotics represents another growing application area for Nitinol foil, where its shape memory and superelastic properties enable the creation of artificial muscles and flexible joints that mimic biological systems. The high power-to-weight ratio of Nitinol foil actuators makes them particularly attractive for small-scale robotic applications where traditional actuators would be too bulky or heavy. Industrial research and development projects increasingly rely on Nitinol foil for prototyping and testing new concepts. The material's unique properties allow researchers to explore novel design approaches that would be impossible with conventional materials, leading to breakthrough innovations in various fields.

Manufacturing Standards and Quality Control

-

Industry Standards and Certifications

Nitinol foil manufacturing adheres to rigorous international standards to ensure consistent quality and performance across all applications. The ASTM F2063 standard specifically governs the composition, mechanical properties, and testing requirements for wrought nickel-titanium shape memory alloys used in medical applications. This standard ensures that Nitinol foil meets strict requirements for chemical composition, transformation temperatures, and mechanical properties. ISO9001 certification ensures that manufacturing processes follow internationally recognized quality management principles, providing customers with confidence in product consistency and reliability. SGS and TUV certifications further validate the quality control systems and manufacturing processes, ensuring that every batch of Nitinol foil meets or exceeds specified requirements. The manufacturing process includes comprehensive testing at multiple stages, from raw material verification to final product inspection. Chemical composition analysis, mechanical property testing, and dimensional verification ensure that each batch of Nitinol foil meets the stringent requirements of its intended application.

-

Quality Assurance and Testing Protocols

Quality control for Nitinol foil manufacturing involves sophisticated testing protocols designed to verify all critical properties and characteristics. Differential scanning calorimetry (DSC) testing determines the precise transformation temperatures, ensuring that the Af temperature falls within the specified range of -10°C to 100°C. Tensile testing verifies the mechanical properties, including ultimate tensile strength, yield strength, and elongation at break. Surface quality inspection ensures that the rolling surface finish meets specified requirements for smoothness and uniformity. Dimensional verification confirms that thickness, width, and length specifications are met within tight tolerances. Each production batch undergoes comprehensive documentation, with production process monitoring documents retained for at least five years to ensure traceability and continuous improvement. Advanced testing equipment and experienced quality control personnel ensure that every aspect of Nitinol foil production meets or exceeds customer expectations. Statistical process control methods help identify potential issues before they affect product quality, ensuring consistent performance across all production batches.

Technical Specifications and Material Options

-

Standard and Custom Specifications

Nitinol foil is available in a comprehensive range of standard specifications designed to meet common application requirements while also offering customization options for specialized needs. Standard thickness options range from 0.05mm minimum for ultra-thin applications to 0.3mm for more robust requirements, with custom thicknesses available upon request. Width specifications accommodate various application needs, from narrow 10mm strips for precision work to wide 300mm sheets for larger components. Length specifications for Nitinol foil typically range from 10mm for small components to 800mm for longer applications, with custom lengths available based on specific requirements. The minimum order quantity of 1kg ensures accessibility for both small-scale research projects and large-scale production runs. Surface finish options include standard rolling finish for most applications, with specialized surface treatments available for specific requirements. Temperature specifications for Nitinol foil include various Af temperature ranges to match application requirements. Standard options include low-temperature activation for body-temperature applications and higher temperature activation for industrial uses. Custom temperature specifications can be developed to meet unique application requirements.

-

Customization and OEM Services

Baoji Hanz Metal Material Co., Ltd. offers comprehensive OEM services to meet specific customer requirements that go beyond standard specifications. Custom alloy compositions can be developed to achieve specific transformation temperatures or mechanical properties for unique applications. Specialized heat treatment processes can modify the properties of Nitinol foil to optimize performance for specific operating conditions. Custom packaging and shipping options ensure that Nitinol foil arrives in optimal condition for immediate use. Waterproof paper wrapping protects against moisture, while plastic protective layers provide additional security during transport. Carton or wooden case packaging options accommodate different quantity requirements and shipping methods. Technical support services include assistance with material selection, application engineering, and process optimization. Experienced engineers work closely with customers to ensure that Nitinol foil specifications match application requirements and performance expectations. Ongoing technical support helps optimize the use of Nitinol foil throughout the product development and production phases.

Conclusion

Nitinol strip and Nitinol foil represent revolutionary advancements in special metal and machined parts, offering unique combinations of superelasticity, shape memory, and biocompatibility that enable breakthrough solutions across multiple industries. From life-saving medical devices to cutting-edge industrial applications, these materials continue to push the boundaries of what's possible in modern engineering and manufacturing.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Partner with Baoji Hanz Metal Material Co., Ltd., a leading China Nitinol foil manufacturer and China Nitinol foil supplier with over 15 years of expertise in Nitinol shape memory alloy and superelastic Nitinol alloy production. As a trusted China Nitinol foil factory, we offer competitive Nitinol foil prices and High Quality Nitinol foil for sale through our comprehensive wholesale services. Our advanced R&D capabilities, ISO9001/SGS/TUV certifications, and global service network of 5000+ customers ensure reliable partnerships with fast delivery, cost advantages, and OEM customization. Contact baojihanz-niti@hanztech.cn for inquiries.

FAQ

Q: What is the minimum thickness available for Nitinol foil?

A: The minimum thickness for Nitinol foil is 0.05mm, with custom thinner options available through special processing.

Q: What temperature range is suitable for Nitinol foil applications?

A: Nitinol foil operates effectively with Af temperatures ranging from -10°C to 100°C, depending on specific alloy composition.

Q: What industries commonly use Nitinol strip and foil materials?

A: Primary industries include medical devices, dental orthodontics, aerospace, robotics, and industrial research applications.

Q: What standards does Nitinol foil manufacturing follow?

A: Nitinol foil production adheres to ASTM F2063 standards along with ISO9001, SGS, and TUV quality certifications.

References

1. Otsuka, K., & Wayman, C.M. "Shape Memory Materials: Fundamentals and Applications" Cambridge University Press

2. Duerig, T., Pelton, A., & Stöckel, D. "An Overview of Nitinol Medical Applications" Journal of Materials Engineering and Performance

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M.A. "A Review of Shape Memory Alloy Research, Applications and Opportunities" Materials & Design

4. Elahinia, M., Hashemi, M., Tabesh, M., & Bhaduri, S.B. "Manufacturing and Processing of NiTi Implants: A Review" Progress in Materials Science