Top 7 Benefits of Using Nitinol Sheet in Manufacturing

2025-08-22 20:09:35

The manufacturing industry is constantly evolving, seeking materials that offer superior performance, durability, and versatility. Among the most revolutionary materials that have emerged in recent decades is the nitinol sheet, a unique nickel-titanium alloy that combines extraordinary properties with practical applications. This comprehensive analysis explores the top seven benefits of incorporating nitinol sheet into manufacturing processes, demonstrating why this shape memory alloy has become indispensable across multiple industries. From medical devices to aerospace components, nitinol sheet offers manufacturers unprecedented advantages that traditional materials simply cannot match, making it a cornerstone of modern advanced manufacturing.

Superior Shape Memory Properties Enable Revolutionary Design Flexibility

The most distinctive advantage of nitinol sheet lies in its remarkable shape memory properties, which allow manufacturers to create components that can return to predetermined shapes when subjected to temperature changes. This unique characteristic stems from the material's crystalline structure transformation between austenite and martensite phases, typically occurring within an Af range of -10 to 100 degrees Celsius. When nitinol sheet is deformed at room temperature and subsequently heated above its transformation temperature, it recovers its original shape with considerable force, enabling the creation of self-actuating mechanisms without external power sources. Manufacturing applications leveraging this property include deployable structures in aerospace, where nitinol sheet components can be compressed for storage and automatically expand when exposed to specific temperatures. The automotive industry utilizes these properties in climate control systems, where nitinol sheet actuators provide precise temperature-responsive control. In medical device manufacturing, this characteristic enables the production of stents and orthodontic wires that can be inserted in a compressed state and then expand to their functional configuration once inside the body. The ability to program multiple shape configurations into a single nitinol sheet component significantly reduces manufacturing complexity while enhancing product functionality.

Exceptional Superelastic Behavior Provides Unmatched Flexibility

Beyond shape memory, nitinol sheet exhibits extraordinary superelastic properties that distinguish it from conventional materials. This superelastic behavior allows the material to undergo significant deformation—up to 10% or more elongation—and return to its original shape upon stress removal, all while maintaining structural integrity. Unlike traditional metals that would permanently deform or fracture under similar stress conditions, nitinol sheet demonstrates remarkable resilience with an ultimate tensile strength exceeding 500 MPa. This superelastic characteristic makes nitinol sheet invaluable in applications requiring repeated flexing or bending without fatigue failure. Manufacturing sectors benefit from this property in creating flexible couplings, vibration dampeners, and spring elements that outperform conventional materials. The telecommunications industry utilizes superelastic nitinol sheet in antenna applications where components must withstand wind loading while maintaining their operational configuration. In consumer electronics, manufacturers incorporate nitinol sheet elements in hinges and flexible connections that must endure thousands of opening and closing cycles without degradation. The combination of high strength and exceptional elasticity enables manufacturers to design lighter, more durable products with extended service life.

Biocompatibility Excellence Opens Medical Manufacturing Opportunities

The exceptional biocompatibility of nitinol sheet has revolutionized medical device manufacturing, making it the material of choice for implantable devices and surgical instruments. Manufactured according to ASTM F2063 standards with a nickel content of 54.7-57% balanced with titanium, nitinol sheet demonstrates excellent corrosion resistance and minimal tissue reaction when implanted in the human body. This biocompatibility, combined with the material's mechanical properties, creates unprecedented opportunities for medical device manufacturers to develop innovative solutions that improve patient outcomes. Medical manufacturing applications include cardiovascular stents, where nitinol sheet's superelastic properties allow for compression during delivery and expansion once positioned. Orthodontic manufacturers utilize nitinol sheet to create archwires that apply consistent, gentle forces throughout treatment, reducing patient discomfort and treatment time. Surgical instrument manufacturers leverage the material's properties to create forceps, guidewires, and other instruments that can navigate complex anatomical pathways while maintaining their functional characteristics. The ability to sterilize nitinol sheet components repeatedly without property degradation ensures long-term reliability in medical applications, making it an essential material for manufacturers serving the healthcare industry.

Temperature-Responsive Actuation Eliminates Complex Control Systems

The temperature-responsive nature of nitinol sheet enables manufacturers to create self-actuating systems that operate without external power sources or complex control mechanisms. This characteristic allows for the development of passive safety systems and automatic controls that respond predictably to environmental temperature changes. When the Af temperature is set above 45 degrees Celsius, nitinol sheet components exhibit pronounced shape memory effects, transitioning from a soft, deformable state at room temperature to a rigid, predetermined configuration when heated. Manufacturing applications include fire safety systems where nitinol sheet actuators automatically open vents or activate sprinkler systems when exposed to elevated temperatures. HVAC manufacturers incorporate nitinol sheet elements in dampers and flow control devices that automatically adjust airflow based on temperature variations. In automotive manufacturing, these components serve as thermal protection devices that activate cooling systems or alter component configurations when operating temperatures exceed safe limits. The reliability and predictability of nitinol sheet's temperature response eliminate the need for sensors, controllers, and external power sources, reducing system complexity while improving reliability and reducing manufacturing costs.

Exceptional Durability and Fatigue Resistance Reduce Maintenance Requirements

Nitinol sheet demonstrates remarkable durability and fatigue resistance that significantly exceed those of conventional materials, making it ideal for applications requiring long-term reliability with minimal maintenance. The material's unique crystalline structure and phase transformation mechanisms enable it to withstand millions of stress cycles without significant degradation, a critical advantage in manufacturing applications where component replacement is costly or impractical. This exceptional durability translates to reduced maintenance costs and improved system reliability across various manufacturing sectors. Aerospace manufacturers utilize nitinol sheet in deployable structures and actuators that must function reliably after years of storage followed by critical deployment. Industrial equipment manufacturers incorporate nitinol sheet components in vibration isolation systems and flexible couplings that operate continuously in harsh environments. The material's resistance to stress corrosion cracking and its ability to maintain properties over extended periods make it particularly valuable in chemical processing equipment where traditional materials would require frequent replacement. Manufacturing facilities benefit from reduced downtime and lower lifecycle costs when nitinol sheet components are properly specified and implemented.

Corrosion Resistance Ensures Long-Term Performance in Harsh Environments

The exceptional corrosion resistance of nitinol sheet makes it invaluable for manufacturing applications in harsh environments where traditional materials would quickly degrade. The material's titanium content provides excellent resistance to various corrosive media, including seawater, acidic solutions, and chloride environments. This corrosion resistance, combined with the material's mechanical properties, enables manufacturers to create components that maintain their performance characteristics over extended periods in challenging operating conditions. Marine manufacturing applications benefit significantly from nitinol sheet's corrosion resistance, particularly in saltwater environments where conventional materials experience rapid deterioration. Chemical processing equipment manufacturers utilize nitinol sheet in components exposed to corrosive chemicals, where the material's resistance to pitting and crevice corrosion ensures long-term reliability. Oil and gas industry manufacturers incorporate nitinol sheet elements in downhole tools and surface equipment where exposure to hydrogen sulfide and other corrosive compounds would quickly damage conventional materials. The combination of corrosion resistance and mechanical properties reduces maintenance requirements and extends equipment service life, providing significant economic advantages to manufacturers and end users alike.

Precision Manufacturing Capabilities Enable Complex Geometries

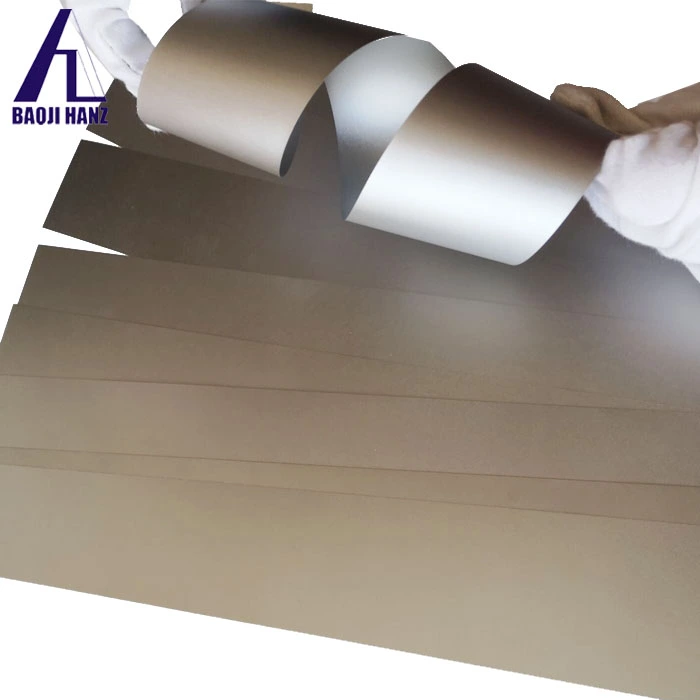

Modern manufacturing techniques have evolved to accommodate the unique properties of nitinol sheet, enabling the production of complex geometries and precise dimensions that would be impossible with traditional materials. Advanced manufacturing processes, including laser cutting, wire EDM, and precision forming, allow manufacturers to create intricate nitinol sheet components with tight tolerances and excellent surface finishes. The material's workability during manufacturing, combined with its transformation properties, enables the creation of components that would require multiple parts if manufactured from conventional materials. Manufacturers can produce nitinol sheet components with thicknesses as thin as 0.1mm and customize dimensions up to 300mm × 800mm, with smaller standard sizes of 100mm × 100mm readily available. This flexibility in manufacturing dimensions allows for optimization of component design and material usage. The ability to set specific transformation temperatures during manufacturing enables customization for particular applications, with Af temperatures ranging from -10 to 100 degrees Celsius. Precision manufacturing capabilities extend to surface treatments and finishing processes that enhance the material's already excellent properties, enabling manufacturers to create components that meet the most demanding specifications while maintaining the unique characteristics that make nitinol sheet superior to conventional alternatives.

Conclusion

The integration of nitinol sheet into manufacturing processes represents a paradigm shift toward more intelligent, efficient, and durable product design. These seven key benefits—superior shape memory properties, exceptional superelastic behavior, biocompatibility excellence, temperature-responsive actuation, exceptional durability, corrosion resistance, and precision manufacturing capabilities—demonstrate why manufacturers across industries are increasingly adopting this revolutionary material. As manufacturing continues to evolve toward more sophisticated and demanding applications, nitinol sheet stands as a critical enabler of innovation and performance enhancement.

At Baoji Hanz Metal Material Co., Ltd., we leverage our 7 years of expertise in Nitinol Shape Memory Alloy, Superelastic Nitinol Alloy, and Nickel Titanium Alloy to provide manufacturers with the highest quality materials and exceptional service. Our direct supply model and cost advantages help you save money while ensuring fast delivery from our large stock of standard sizes. As a leading China nitinol sheet factory and China nitinol sheet supplier, we serve as your trusted China nitinol sheet manufacturer and China nitinol sheet wholesale partner, offering OEM services to meet your specific requirements. Whether you need custom sizes, specific alloy compositions, or specialized packaging options, our team works closely with you to ensure our products fit seamlessly into your projects. Contact us at baojihanz-niti@hanztech.cn to discover how our nitinol sheet solutions can revolutionize your manufacturing processes.

References

1. Otsuka, K., & Wayman, C. M. (1998). Shape Memory Materials: Fundamentals of Martensitic Phase Transformations in Alloys. Cambridge University Press.

2. Duerig, T. W., Melton, K. N., & Stöckel, D. (2013). Engineering Aspects of Shape Memory Alloys: Manufacturing and Applications in Medical Devices. Butterworth-Heinemann.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A Review of Shape Memory Alloy Research, Applications and Opportunities in Aerospace Engineering. Materials & Design, 56, 1078-1113.

4. Pelton, A. R., Dicello, J., & Miyazaki, S. (2000). Optimization of Processing and Properties of Medical Grade Nitinol Wire for Biomedical Applications. Minimally Invasive Therapy & Allied Technologies, 9(2), 107-118.