Ultimate Guide to Nitinol Foil: Everything You Need to Know

2025-09-30 22:40:35

Are you struggling to find the perfect material that combines superelasticity, shape memory properties, and exceptional durability for your demanding applications? Nitinol, short for Nickel Titanium Naval Ordnance Laboratory, is a unique shape memory alloy renowned for its exceptional properties and characteristics. This remarkable material exhibits superelasticity and shape memory effect, allowing it to return to its original shape after deformation. This comprehensive guide to Nitinol Foil will transform your understanding of this revolutionary material, providing you with the essential knowledge to make informed decisions for your medical, industrial, or research applications.

Understanding Nitinol Foil: The Revolutionary Shape Memory Alloy

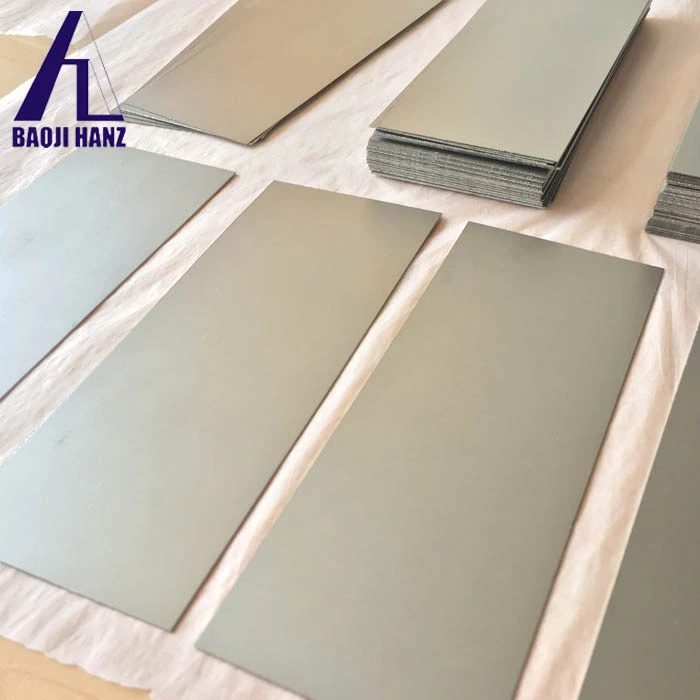

Nitinol foil represents one of the most sophisticated forms of nickel-titanium alloy available in today's market. This ultra-thin material combines the extraordinary properties of nitinol with the versatility and precision required for demanding applications across multiple industries. Nitinol Foil is a nickel-titanium alloy with super elasticity and shape memory properties. The unique atomic structure of nitinol foil enables it to undergo significant deformation while maintaining its ability to return to a predetermined shape when exposed to specific temperature conditions. The manufacturing process of nitinol foil requires exceptional precision and control to achieve the desired thickness while maintaining the material's inherent properties. Professional manufacturers like Baoji Hanz Metal Material Co., Ltd. utilize advanced production techniques to create nitinol foil with consistent quality and performance characteristics. The superelastic nitinol material composition typically contains 54.5% to 57% nickel, with the balance being titanium, creating an optimal blend that delivers both mechanical strength and thermal responsiveness.

-

Properties That Make Nitinol Foil Exceptional

The exceptional properties of nitinol foil stem from its unique crystalline structure, which undergoes reversible phase transformations between austenite and martensite phases. This transformation gives nitinol foil its signature shape memory effect and superelasticity characteristics that make it invaluable in countless applications. Nitinol is superelastic (10X as flexible as other metals), and its thermal shape memory properties are unlike any other material available. Applications with tight space requirements often use nitinol when conventional mechanisms cannot fit. The superelastic nature of nitinol foil allows it to withstand strains of up to 8% while still returning to its original configuration, far exceeding the capabilities of traditional metallic materials. The austenite finish (Af) temperature range of nitinol foil, typically spanning from -10 degrees to 100 degrees Celsius, determines the temperature at which the material completes its transformation to the austenite phase. This controllable characteristic enables engineers and designers to tailor nitinol foil applications to specific operational requirements, making it ideal for temperature-sensitive applications in medical devices, robotics, and industrial automation systems.

Technical Specifications and Manufacturing Standards

High-quality nitinol foil production requires adherence to stringent technical specifications and international standards to ensure consistent performance and reliability. The ASTM F2063 standard provides comprehensive guidelines for nitinol material properties, testing procedures, and quality control measures that reputable manufacturers must follow to deliver superior products. Manufacturing specifications for premium nitinol foil include precise thickness control ranging from 0.05mm to 0.3mm, width dimensions from 10mm to 300mm, and length options from 10mm to 800mm to accommodate diverse application requirements. The rolling surface finish ensures optimal surface quality while maintaining the material's mechanical properties throughout the manufacturing process.

-

Chemical Composition and Quality Control

The chemical composition of nitinol foil plays a crucial role in determining its performance characteristics and application suitability. Professional manufacturers maintain strict control over the nickel content, ensuring it falls within the optimal range of 54.5% to 57%, with titanium comprising the balance of the alloy composition. This precise chemical balance is essential for achieving the desired transformation temperatures and mechanical properties. Quality control procedures include comprehensive testing of each production batch to verify chemical composition, transformation temperatures, mechanical properties, and surface quality. Advanced testing equipment enables manufacturers to conduct thorough inspections, ensuring every nitinol foil shipment meets or exceeds customer specifications and international quality standards. Certification compliance with ISO9001, SGS, and TUV guidelines demonstrates a manufacturer's commitment to quality excellence and customer satisfaction. These certifications provide customers with confidence in product quality and manufacturing processes, supporting long-term business relationships and project success.

Applications Across Multiple Industries

Nitinol foil applications span numerous industries, each leveraging the material's unique properties to solve complex engineering challenges and improve product performance. The versatility of nitinol foil makes it an indispensable material for applications requiring precise actuation, exceptional durability, and reliable performance under demanding conditions.

-

Medical and Dental Applications

The biocompatibility and superelastic properties of nitinol foil make it ideal for medical and dental applications where conventional materials fall short. Nitinol Foil is highly biocompatible and has properties suitable for use in orthopedic implants. Nitinol Foil has seen a large demand for use in less invasive medical devices. Dental orthodontic applications benefit significantly from nitinol foil's ability to provide consistent, gentle forces over extended periods while maintaining shape memory characteristics. Surgical instruments incorporating nitinol foil components offer surgeons enhanced precision and control during delicate procedures. The material's ability to undergo significant deformation without permanent damage enables the development of minimally invasive surgical tools that can navigate complex anatomical pathways while maintaining their functional capabilities. Cardiovascular applications utilize nitinol foil in stent manufacturing, where the material's superelastic properties enable device deployment through small delivery systems while providing optimal vessel support after deployment. The corrosion resistance and biocompatibility of nitinol foil ensure long-term implant success and patient safety.

-

Industrial and Research Applications

Industrial applications of nitinol foil encompass automation systems, robotics, and precision manufacturing equipment where reliable actuation and exceptional durability are essential. The material's ability to generate substantial forces while maintaining compact dimensions makes it ideal for applications with strict space constraints and performance requirements. Research institutions and development laboratories utilize nitinol foil for experimental applications, prototype development, and advanced materials research. The predictable and repeatable characteristics of nitinol foil enable researchers to develop innovative solutions for complex engineering challenges across multiple disciplines. Robotic systems incorporate nitinol foil actuators to achieve smooth, silent operation with high force output capabilities. The material's unique properties enable the development of biomimetic actuators that replicate natural muscle movement patterns while providing superior performance characteristics compared to traditional actuator technologies.

Sourcing and Supply Chain Considerations

Selecting the right nitinol foil supplier is crucial for project success and long-term material supply security. Established manufacturers with proven track records, comprehensive quality systems, and global supply capabilities provide customers with the reliability and support necessary for demanding applications.

-

Choosing the Right China Nitinol Foil Manufacturer

When evaluating potential China Nitinol Foil suppliers, consider factors such as manufacturing experience, quality certifications, technical support capabilities, and customer service excellence. Reputable China Nitinol Foil manufacturers like Baoji Hanz Metal Material Co., Ltd. offer comprehensive services including technical consultation, custom manufacturing, and after-sales support to ensure customer success. Production capacity and delivery reliability are essential considerations when selecting a China Nitinol Foil factory for your supply needs. Manufacturers with substantial inventory levels and flexible production capabilities can accommodate both small-scale research requirements and large-volume industrial applications while maintaining consistent quality standards. Cost-effectiveness without compromising quality should be a primary consideration when sourcing from China Nitinol Foil wholesale suppliers. Direct manufacturer relationships often provide significant cost advantages while ensuring access to technical expertise and customization capabilities that distributors may not offer.

Conclusion

Nitinol Foil combines shape memory effect, superelasticity, and high corrosion resistance in a thin, flexible form, enabling precise actuation and long-term durability in compact designs. This comprehensive guide has explored the essential aspects of nitinol foil technology, applications, and sourcing considerations to support informed decision-making for your specific requirements.

Cooperate with Baoji Hanz Metal Material Co., Ltd.

Partner with Baoji Hanz Metal Material Co., Ltd., your trusted China Nitinol Foil manufacturer and China Nitinol Foil supplier, featuring over 15 years of expertise in superelastic nitinol alloy production. As a leading China Nitinol Foil factory, we offer China Nitinol Foil wholesale pricing with High Quality Nitinol Foil for sale at competitive Nitinol Foil prices. Our ISO9001, SGS, and TUV certified facility serves 5000+ global customers with comprehensive pre-sale consultation, order tracking, and after-sales support. Contact us at baojihanz-niti@hanztech.cn for your requirements.

FAQ

Q: What is the minimum thickness available for nitinol foil?

A: Professional manufacturers can produce nitinol foil with thickness starting from 0.05mm, with standard ranges from 0.05mm to 0.3mm depending on application requirements.

Q: What temperature range activates nitinol foil shape memory properties?

A: Nitinol foil typically has an austenite finish temperature range from -10°C to 100°C, which can be customized based on specific application needs.

Q: Is nitinol foil suitable for medical device applications?

A: Yes, nitinol foil is highly biocompatible and meets ASTM F2063 standards, making it ideal for dental orthodontics, surgical instruments, and medical implants.

Q: What is the minimum order quantity for nitinol foil?

A: Most professional manufacturers offer minimum order quantities starting from 1kg to accommodate both research and commercial applications.

References

1. "Shape Memory Alloys: Properties, Technologies, Opportunities" by K. Otsuka and C.M. Wayman, Cambridge University Press

2. "Nitinol Shape Memory Alloys: Fundamentals and Applications" by D.C. Lagoudas, Springer Science & Business Media

3. "Medical Applications of Nitinol Shape Memory Alloys" by T.W. Duerig, A. Pelton, and D. Stoeckel, Materials Science Forum

4. "ASTM F2063-18 Standard Specification for Wrought Nickel-Titanium Shape Memory Alloys for Medical Devices and Surgical Implants" by ASTM International Standards