What Is the Role of Nitinol Wire Medical in Cardiovascular Devices?

2025-09-19 20:32:04

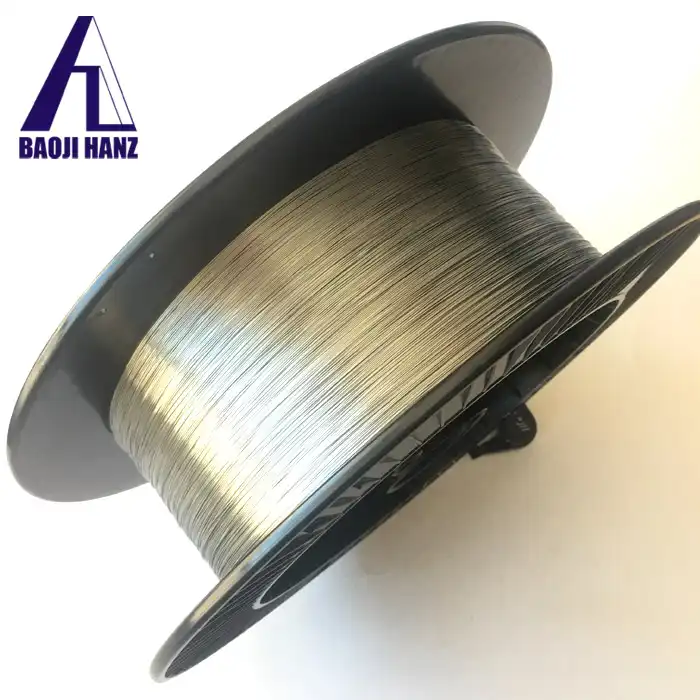

Nitinol wire medical plays a transformative role in modern cardiovascular devices, revolutionizing how medical professionals approach cardiac interventions and vascular treatments. This remarkable nickel-titanium alloy is now widely used for many medical components, including reinforcement braiding and coiling for catheter tubing and shafts, braided and formed stents, and formed retrieval baskets, particularly in cardiovascular implants and devices for removing blood clots. The unique superelastic properties and shape memory characteristics of nitinol wire medical enable cardiovascular devices to navigate complex vascular pathways while maintaining structural integrity and optimal performance. These extraordinary capabilities have made nitinol wire medical an indispensable material in the development of minimally invasive cardiovascular procedures, offering patients safer treatment options with improved outcomes and reduced recovery times.

Essential Properties of Nitinol Wire Medical for Cardiac Applications

Superelastic Behavior in Vascular Environments

The superelastic properties of nitinol wire medical represent one of its most valuable characteristics for cardiovascular applications. Nitinol exhibits both superelasticity and thermal shape memory behaviour, making it widely used as a biocompatible metal with applications in high strain medical devices. This superelasticity allows cardiovascular devices to undergo significant deformation during insertion through tortuous blood vessels while automatically returning to their predetermined shape once deployed. The material can withstand strains up to 8% without permanent deformation, which is particularly crucial for stents and guidewires that must navigate through curved arteries and veins. This property ensures that cardiovascular devices maintain their structural integrity throughout complex procedures, providing consistent performance even under extreme mechanical stress. The superelastic behavior also contributes to the device's ability to conform to the natural curvature of blood vessels, reducing the risk of vessel trauma and improving patient comfort during procedures.

Shape Memory Capabilities in Cardiac Device Design

Shape memory functionality in nitinol wire medical enables cardiovascular devices to transition between different configurations based on temperature changes within the body. The shape memory properties of the nitinol wire struts in transcatheter heart valves allow them to collapse down into a catheter for delivery and then expand inside a patient's heart. This remarkable capability allows complex cardiac devices to be compressed into small delivery systems and then automatically expand to their functional shape once they reach body temperature. The transformation temperature of medical-grade nitinol is carefully controlled to occur just below body temperature, ensuring reliable deployment in cardiovascular applications. This property is particularly valuable in transcatheter aortic valve replacement procedures, where large valve structures must be delivered through small arterial access points. The shape memory effect also provides a fail-safe mechanism, as devices will naturally assume their intended configuration even if deployment procedures encounter unexpected challenges, thereby enhancing procedural success rates and patient safety.

Biocompatibility and Corrosion Resistance in Blood Contact

The exceptional biocompatibility of nitinol wire medical makes it ideally suited for long-term implantation in cardiovascular environments where direct blood contact is inevitable. The material exhibits excellent corrosion resistance in physiological conditions, with a protective titanium oxide layer that forms naturally on the surface, preventing harmful ion release into the bloodstream. This surface characteristic significantly reduces the risk of thrombosis and inflammatory responses, which are critical considerations for permanent cardiovascular implants such as stents and valve components. The biocompatibility extends beyond mere tolerance, as nitinol wire medical actually promotes endothelialization in vascular applications, allowing natural tissue growth over implanted devices. Clinical studies have demonstrated that nitinol-based cardiovascular devices maintain their mechanical properties and surface integrity over extended periods, with minimal degradation even after years of cyclic loading in the demanding cardiovascular environment. This combination of biocompatibility and durability makes nitinol wire medical an optimal choice for devices requiring permanent implantation in cardiac applications.

Manufacturing Technologies for Cardiovascular Nitinol Wire Medical

Advanced Processing Techniques for Medical Grade Standards

The production of nitinol wire medical for cardiovascular applications requires sophisticated manufacturing processes that ensure consistent quality and performance. Medical nitinol processing transforms raw nickel-titanium (NiTi) alloy into wire, coils, tubes and sheets for medical and dental devices through carefully controlled procedures. Vacuum induction melting is employed to create the initial alloy, followed by precise rolling and drawing processes that achieve the ultra-fine diameters required for cardiovascular applications. The manufacturing process includes multiple annealing steps to optimize the transformation temperatures and mechanical properties specific to cardiac device requirements. Heat treatment protocols are meticulously controlled to ensure uniform microstructure throughout the wire length, eliminating variations that could affect device performance. Surface finishing techniques, including electropolishing and passivation, create the smooth, corrosion-resistant surfaces essential for blood-contacting applications. Quality control measures throughout manufacturing include dimensional verification, mechanical testing, and biocompatibility assessment to ensure every batch meets the stringent requirements of cardiovascular device manufacturers.

Precision Engineering for Ultra-Fine Wire Specifications

The cardiovascular industry demands nitinol wire medical with extremely precise dimensions and tolerances, particularly for applications in minimally invasive procedures. Nitinol wire in this form is a great choice for medical devices that may be introduced into the body to perform surgical procedures, and their mechanical properties play a significant role in the selection of metal for cardiovascular or neural surgeries. Manufacturing processes must achieve wire diameters ranging from 0.02mm to several millimeters while maintaining consistent mechanical properties along the entire length. Advanced drawing techniques utilize diamond dies and controlled atmosphere processing to prevent surface defects that could compromise device performance or biocompatibility. The precision engineering extends to the control of transformation temperatures, with specifications typically maintained within ±5°C to ensure predictable deployment characteristics in cardiovascular applications. Surface roughness is controlled to sub-micron levels to minimize thrombogenicity and optimize blood flow characteristics around implanted devices. These manufacturing capabilities enable the production of guidewires, stent struts, and catheter components that meet the exacting requirements of modern cardiovascular interventions.

Quality Assurance and Compliance Standards

Manufacturing nitinol wire medical for cardiovascular applications requires adherence to the highest quality standards and regulatory compliance. Production facilities must maintain ISO 13485 certification and comply with FDA Good Manufacturing Practices to ensure consistent quality and traceability. Each production batch undergoes comprehensive testing including tensile strength verification, fatigue resistance evaluation, and transformation temperature validation to confirm compliance with ASTM F2063 standards. Biocompatibility testing according to ISO 10993 standards ensures that materials meet the requirements for permanent implantation in cardiovascular applications. Advanced non-destructive testing methods, including ultrasonic inspection and eddy current testing, detect internal defects that could compromise device performance. Chemical composition analysis using X-ray fluorescence and inductively coupled plasma spectroscopy verifies the precise nickel-titanium ratio required for optimal properties. Documentation systems maintain complete traceability from raw material sources through final product delivery, enabling rapid response to any quality issues and supporting regulatory submissions for cardiovascular device approvals.

Clinical Applications in Cardiovascular Device Engineering

Stent Technology and Vascular Intervention Applications

Nitinol wire medical has revolutionized stent technology, enabling the development of self-expanding devices that provide superior performance in complex vascular anatomies. Self-expanding nitinol stents offer exceptional fatigue resistance and provide advantages in challenging deployment environments, making them particularly valuable for treating peripheral artery disease and carotid artery stenosis. The superelastic properties allow stents to maintain consistent radial force against vessel walls while accommodating natural vessel movement during cardiac cycles. Braided nitinol wire constructions provide optimal flexibility for navigating tortuous vessels while maintaining sufficient radial strength to resist vessel recoil. The material's fatigue resistance ensures long-term performance under the demanding conditions of pulsatile blood flow, with laboratory testing demonstrating millions of cycles without failure. Self-expanding nitinol stents can be precisely sized to vessel dimensions, providing optimal apposition and reducing the risk of migration or edge effects. These characteristics have made nitinol wire medical the preferred material for next-generation stent designs that prioritize patient outcomes and procedural success.

Cardiac Catheter and Guidewire Development

The development of advanced cardiac catheters and guidewires relies heavily on the unique properties of nitinol wire medical to achieve the delicate balance between flexibility and strength required for complex cardiac procedures. Many customers are choosing to use nitinol for coiled catheters in especially sensitive surgeries where accuracy is of utmost importance, such as cardiovascular surgeries. Guidewires incorporating nitinol wire medical can navigate through severely stenotic vessels while maintaining tip integrity and tactile feedback for physicians. The superelastic properties enable catheters to follow complex anatomical pathways without kinking or permanent deformation, reducing procedure time and improving success rates. Reinforcement braiding using ultra-fine nitinol wire provides exceptional torque transmission while maintaining flexibility, allowing precise device positioning in challenging anatomical locations. The biocompatibility of nitinol wire medical reduces the risk of thrombus formation during extended procedures, enhancing patient safety. These applications have enabled the development of increasingly sophisticated cardiac intervention techniques, including complex coronary interventions and structural heart procedures that were previously considered inoperable.

Transcatheter Valve and Structural Heart Applications

Nitinol wire medical plays a crucial role in the development of transcatheter heart valves and other structural heart devices that require precise deployment and long-term durability. The shape memory properties of the nitinol wire struts allow transcatheter valves to collapse down into a catheter for delivery and then expand inside a patient's heart, enabling minimally invasive treatment of valvular heart disease. The material's combination of radial strength and flexibility ensures optimal valve seating while maintaining leaflet mobility for proper hemodynamic function. Nitinol wire frameworks provide the structural support necessary for valve leaflets while allowing natural cardiac motion without fatigue failure. The self-expanding characteristics enable precise valve positioning and optimal contact with native tissue structures, reducing paravalvular leakage. Advanced manufacturing techniques create complex three-dimensional nitinol structures that replicate natural valve geometry while accommodating individual patient anatomy. These applications have transformed the treatment of aortic stenosis and other valvular diseases, offering therapeutic options to high-risk patients who were previously ineligible for surgical intervention. The continued evolution of nitinol wire medical technology promises to expand treatment possibilities for an even broader range of structural heart conditions.

Conclusion

The role of nitinol wire medical in cardiovascular devices represents a paradigm shift in cardiac intervention technology, offering unprecedented capabilities for minimally invasive treatments. The unique combination of superelasticity, shape memory properties, and biocompatibility has enabled the development of sophisticated devices that improve patient outcomes while reducing procedural risks. From self-expanding stents to transcatheter heart valves, nitinol wire medical continues to drive innovation in cardiovascular medicine, making complex procedures safer and more accessible to patients worldwide.

As a leading China nitinol wire medical factory, Baoji Hanz Metal Material Co., Ltd. stands ready to support your cardiovascular device development needs. Our expertise as a premier China nitinol wire medical supplier and China nitinol wire medical manufacturer ensures access to the highest quality materials for your applications. With over 7 years of expertise in nitinol shape memory alloys and direct supply cost advantages, we offer competitive nitinol wire medical prices and fast delivery from our extensive stock. We provide customized nitinol wire medical solutions and nitinol wire medical for sale to meet your specific requirements, including nitinol wire medical free samples for evaluation. Our wholesale capabilities and OEM services ensure seamless integration into your projects. Contact us at baojihanz-niti@hanztech.cn to discuss your nitinol wire medical requirements and experience the quality and service that sets us apart in the industry.

References

1. Duerig, Thomas W., and Alan R. Pelton. "An overview of nitinol medical applications." Materials Science and Engineering: A, Vol. 273-275 (1999): 149-160.

2. Morgan, Neil B. "Medical shape memory alloy applications—the market and its products." Materials Science and Engineering: A, Vol. 378, No. 1-2 (2004): 16-23.

3. Stoeckel, Dieter, Andreas Pelton, and Thomas Duerig. "Self-expanding nitinol stents: material and design considerations." European Radiology, Vol. 14, No. 2 (2004): 292-301.

4. Rebelo, Nuno, et al. "Finite element analysis for the design of nitinol medical devices." Minimally Invasive Therapy & Allied Technologies, Vol. 18, No. 3 (2009): 141-148.