Nitinol Steps Into the Limelight

2025-11-14 21:07:17

Nitinol Steps Into the Limelight: Innovations in Medicine and Beyond Drive the Alloy’s Growth

Nitinol—nickel-titanium alloy—has become a true driver of progress in 2025, transforming industries from minimally invasive healthcare to aerospace and wearables thanks to two standout traits: shape memory effect and superelasticity. Powered by atomic phase shifts between austenite and martensite, the alloy bounces back to its preset form when exposed to temperature or stress, and handles extreme bending without permanent damage—making it a go-to material for cutting-edge solutions.

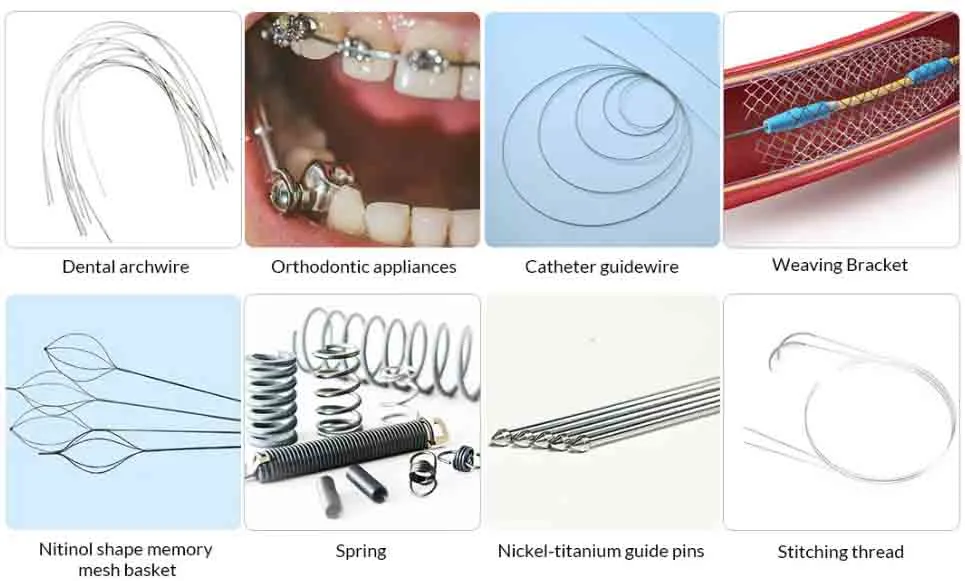

The medical field remains nitinol’s biggest success story, with 2025 bringing game-changing strides in cardiovascular care. Absorbable nitinol scaffolds, paired with biodegradable polymer coatings and nanotech, now deliver controlled drug release, dropping vascular restenosis rates to under 5%. For tricky coronary bifurcation lesions, fractal-designed nitinol stents fit vessel structures seamlessly, fixing the coverage gaps of older devices. In neurointervention, dense-mesh nitinol flow diverters treat intracranial aneurysms by redirecting blood flow, while upgraded thrombectomy stents boost large-clot removal efficiency. Beyond blood vessels, nitinol fuels next-gen treatments: pulse field ablation catheters cut tissue damage by 70% versus radiofrequency methods, and robotic-assisted heart valve systems depend on self-expanding nitinol frames for less invasive replacements.

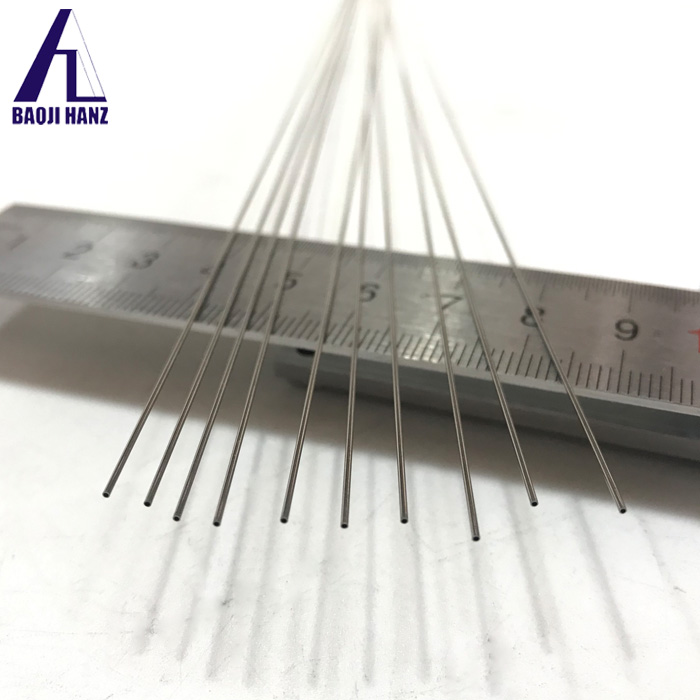

Manufacturing innovations are expanding nitinol’s reach. Wire Arc Additive Manufacturing (WAAM) combined with precise heat treatment now produces biomedical-grade nitinol with 98% superelastic recovery—matching the performance of traditionally forged alloy. 4D printing pushes boundaries further, creating nitinol implants that expand on their own at body temperature and adapt as tissues heal. The material is also popping up in smart medical devices: nitinol stents fitted with micro-sensors track intravascular pressure and pH in real time, sending data wirelessly for personalized patient care.

Beyond medicine, nitinol’s versatility shines in consumer and industrial sectors. Taking cues from NASA’s Mars rover tire tech, wearable brands now use nitinol microfilaments to make footwear that conforms to individual foot shapes and stands up to high impact. Its superelasticity—8-10% strain capacity, way more than stainless steel’s 0.5%—makes it perfect for aerospace actuators and industrial seals that need to last in extreme conditions.

Industry moves highlight nitinol’s rising importance: 2024-2025 saw major deals, like Johnson & Johnson’s $1.7B acquisition of V-Wave for its nitinol heart failure shunt, plus production expansions to keep up with 25% yearly demand growth. Resonetics now holds 40% of the global medical-grade nitinol market, while partnerships like Confluent and ATI have cut melting cycles in half, to just four weeks.

Challenges linger—supply shortages and long-term biocompatibility checks chief among them. Regulators like the EMA now require 20 years of follow-up data for implanted nitinol devices. But with ongoing advances in surface modification and smart tech integration, nitinol’s role in redefining treatment standards, product performance, and human-machine interaction keeps growing.

From life-saving stents to space-inspired wearables, nitinol’s ability to “remember” its shape and bounce back is proving that the future of advanced materials is all about adaptability. As research unlocks new formulas and uses, this remarkable alloy is set to shape innovation across sectors for years to come.

Contact Us

Baoji Hanz Metal Material Co., Ltd.

Gaoxin Avenue, BaoJi city, ShaanXi province China

Tel: 86-917-3258889

Mobile, Whatsapp,Wechat: +8618091719909

Email:baojihanz-niti@hanztech.cn

_1740043052871.webp)