Nickel-titanium springs are functional components manufactured based on the properties of nickel-titanium shape memory alloys (SMA). They are widely used in medical, aerospace, and electronics fields. Their production process requires strict control over composition, microstructure, and mechanical properties, revolving around five key stages: material preparation, forming, heat treatment, post-processing, and performance testing.

How to make a perfect nitinol titanium spring?

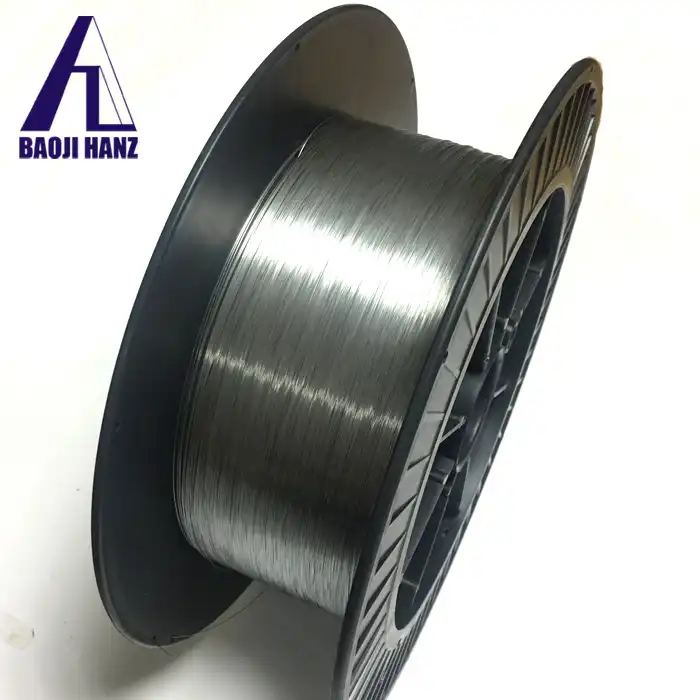

I. Prepare Core Raw Material : Nickel-Titanium Alloy Rods/Wires

The performance of nickel-titanium springs relies heavily on the uniformity of the nickel-titanium alloy composition (nickel content is typically 50.5%~51.2% (atomic ratio), requiring precise control to ensure shape memory effect and super elasticity). This stage forms the foundation of the process.

High-purity raw materials are used: sponge titanium (purity ≥99.7%) and electrolytic nickel (purity ≥99.9%), precisely weighed according to the designed composition (error must be controlled within ±0.1% atomic ratio to avoid phase transformation temperature drift caused by nickel content deviation).

Smelting process: Vacuum induction melting (VIM) or vacuum arc melting (VAR) are the mainstream methods. One to two remelting processes eliminate compositional segregation, obtaining a uniform nickel-titanium master alloy ingot (typically 50-150mm in diameter).

Plastic Working: Preparation of Alloy Rods/Wires

Ni-titanium alloys have poor plasticity at room temperature and require a combination of hot and cold working to prepare spring blanks (rods or wires, diameter determined by spring specifications; medical spring wire diameters can be as small as 0.1mm):

Hot Forging/Hot Rolling: The alloy ingot is heated to 800~950℃ (β phase region, the high-temperature stable phase of nickel-titanium alloy), and then forged or rolled into rods with a diameter of 20~50mm to break up the casting structure and refine the grains.

Cold Drawing/Cold Rolling: The hot-worked rods are gradually cold-drawn (or cold-rolled) to the target diameter, with each deformation controlled at 5%~15% (to avoid excessive deformation in a single step leading to material brittleness). Intermediate annealing (700~800℃, holding for 10~30min) is required to eliminate work hardening and restore plasticity.

Surface treatment: After cold working, the surface oxide scale is removed by pickling (mixed solution of nitric acid and hydrofluoric acid) to ensure the surface smoothness of the blank (Ra≤0.8μm) and avoid stress concentration during subsequent molding.

Depending on the spring's structure (compression, tension, torsion) and precision requirements, different forming processes are selected. The core is to ensure the spring's geometric dimensions remain stable and that no significant deformation occurs after subsequent heat treatment.

II. Winding Forming (Mainstream Process)

Equipment: A CNC spring winding machine is used, which can precisely control the winding speed (50~200 r/min), pitch (0.1~5 mm), and number of turns (1~100 turns). It is suitable for regular springs such as cylindrical and conical shapes.

Die: The mandrel is selected according to the spring's inner diameter (the material is mostly high-speed steel or hard alloy to avoid adhesion with nickel-titanium alloy). During winding, the mandrel speed and wire feed speed must be matched to prevent "loose coils" or "overlapping coils" in the spring.

For irregularly shaped springs (such as variable diameter and variable pitch springs), laser cutting is used (first, nickel-titanium alloy plates/tubes are processed into blanks, then the spring shape is cut using a fiber laser, with an accuracy of ±0.01mm).

Miniature springs (such as springs for medical vascular stents) are formed using micro-electroforming or precision injection molding (requiring nickel-titanium powder metallurgy blanks), but the cost is higher, suitable for high-precision applications.

III. Imparting Shape Memory/Superelasticity nitinol spring

The core properties of nickel-titanium springs (shape memory effect, superelasticity, phase transition temperature) are all achieved through heat treatment. This stage is the core of the process, requiring strict control of temperature, holding time, and cooling rate.

Process parameters: Heat to 900~1050℃ (β phase region), hold for 10~60min (adjust according to billet size; shorter holding time for wire, longer for bar), followed by water quenching (cooling rate ≥100℃/s) to prevent the β phase from decomposing into the brittle Ti₂Ni phase.

Aging treatment: Controlling phase transformation temperature and mechanical properties

Shaping Process: Fixing the Spring Geometry

After winding, the spring needs to be low-temperature shaped in a shaping mold (temperature typically 150~300℃, held for 10~30 minutes). The purpose is to fix the spring's pitch, number of turns, and other geometric parameters to prevent "creep" during subsequent use, especially suitable for precision medical springs.

_1764830803274.jpg)