Nitinol alloy wire brief introduction

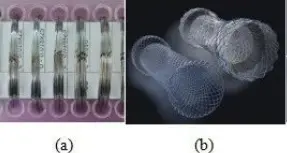

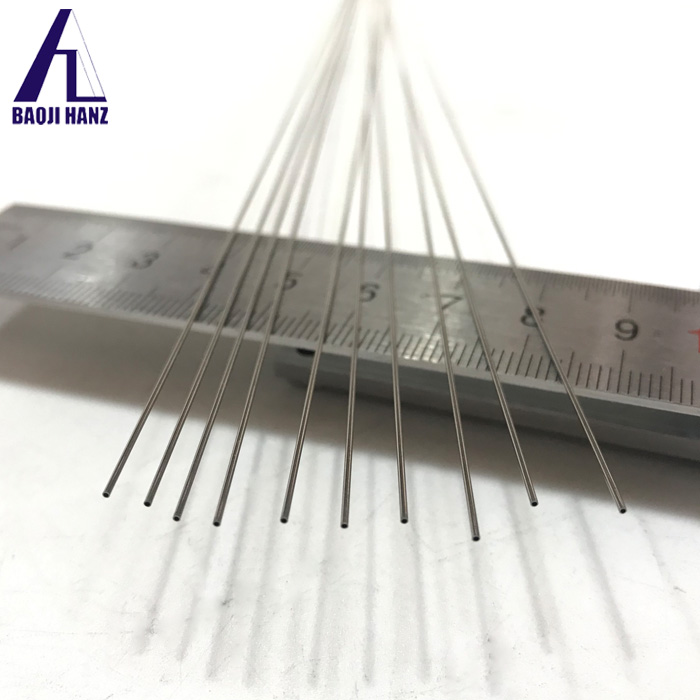

Nickel-titanium alloy is considered one of the best materials for living organisms due to its advantages such as good shape memory, resistance to corrosion, biocompatibility and ability to work in living organisms, and thus is widely used in construction, military and other industries. Nitinol alloy wire plays an important role in surgery because of its properties mentioned above. For example, as a guide wire, it can easily compress complex blood vessels using its flexibility. The nickel-titanium wire commonly used in medicine is widely used in surgery, dentistry, orthopedics, prosthetics, etc. The actual morphologies are shown in below picture.

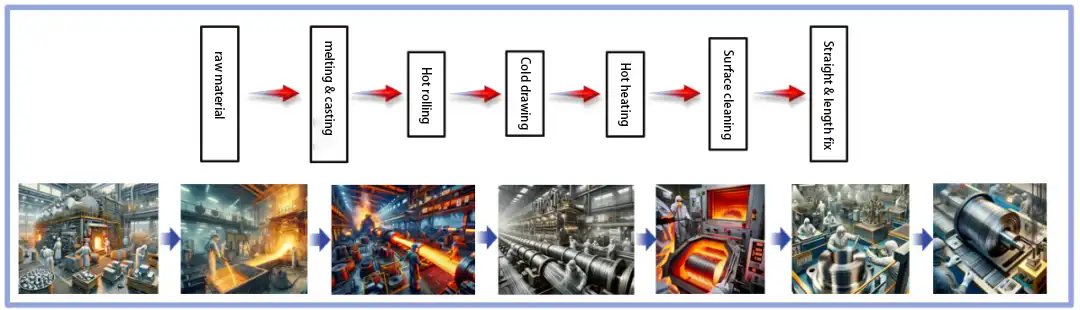

Nitinol alloy wire is a highly structured material with the effect of memory and ductility, which is widely used in medical devices, aerospace equipment, intelligent controls and other fields. Its unique physical and chemical properties make the production process very difficult and demanding. The preparation of nickel and titanium alloy wires mainly involves the following basic steps as shown in below photo:

Nitinol alloy wire manufacture process steps

The first step is the preparation of the raw materials.

NiTi alloys are commonly used as raw materials in the form of nitinol ingots. These raw materials need to go through a rigorous inspection process to ensure that their quality meets the requirements. The uniformity and purity of the alloy composition is the basis for ensuring the quality of the final product.

The second is the fermentation and fermentation process.

The annealing of NiTi steels is usually done by vacuum annealing or arc annealing methods. These processes can effectively prevent the alloy from evaporating when it comes into contact with air at high temperatures, ensuring the purity and uniformity of the alloy. The molten alloy solution is formed into billets through the casting process. These billets are usually in the form of bars or plates, which provide the basis for the subsequent hot and cold processing.

Third, heat treatment is one of the key steps in the fabrication of NiTi alloy wires. The billets after casting need to be molded and rolled at high temperatures to improve the grain structure and improve the mechanical properties of the product. The alloy materials after annealing are usually rolled into bars or plates of larger diameter.

Fourth, after hot processing, the cold drawing process processes large diameter metals or plates into thin wires. This process usually requires multiple cold cycles, and moderate care is required after each cold cycle. Cold drawing is one of the key steps in the processing of nickel and titanium alloy wire. By gradually reducing the diameter of the wire, its accuracy and consistency can be controlled. Heating is carried out after each cold drawing to eliminate the stress created during cold working, to restore the plasticity and ductility of the material, and to ensure the continuity and stability of the wire during the drawing process.

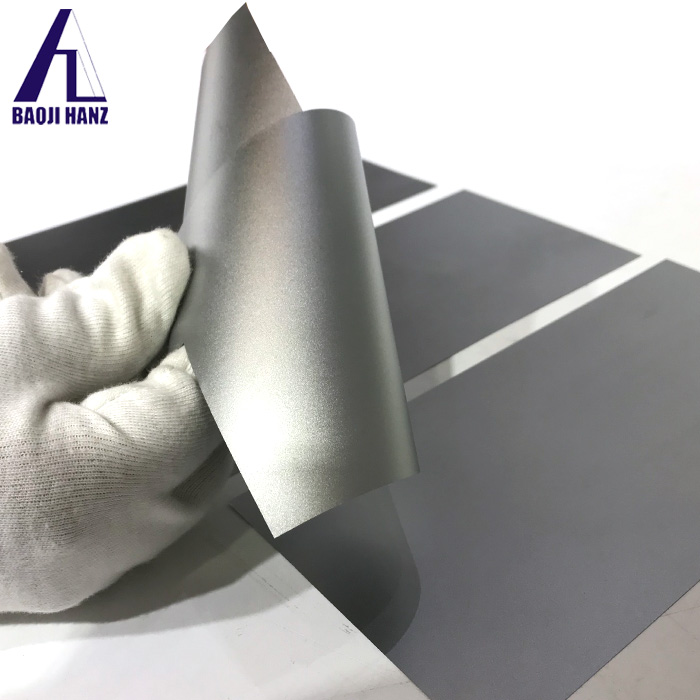

Fifth, surface treatment is another important link in the processing of nitinol alloy wire. There may be scratches and impurities on the surface of the wire after cold ringing and tempering. These defects need to be removed by methods such as polishing or electrospinning. Surface treatment can not only improve the finish of the wire, but also improve the corrosion resistance and surface quality, in order to meet the highest application requirements.

Eventully, the prepared nickel-titanium alloy wire is straightened and sized to ensure that the straightness and length of the wire meet the customer's requirements. After rigorous performance testing, including mechanical properties, surface quality and measurement accuracy, the nitinol alloy wire was confirmed to meet the standards.

All in all, cold drawing, annealing and surface treatment are the most important steps in the processing of nickel-titanium composite wire. Cold drawing ensures the accuracy and consistency of the wire, annealing ensures the machinability and ductility of the material, and surface treatment directly affects the final quality and application effect of the wire.

Main specification of Nitinol alloy hot drawing wire

| Diameter/mm | Hot drawing method | Temperature/℃ | wire speed(m/s-1) | pass reduction/mm |

| 8.5-6.5 | Direct electric heating | 760-800 | 2-3 | 1-0.5 |

| 6.5-3.0 | Direct electric heating | 650-750 | 3-5 | 0.5-0.3 |

| 3.0-3.2 | Electric heating radiation heating | 600-650 | 5-9 | 0.3-0.25 |

| 2.0-0.8 | Electric heating radiation heating | 600-650 | 9-12 | 0.25-0.08 |

| 0.8-0.5 | Electric heating radiation heating | 500-600 | 12-15 | 0.08-0.04 |

| 0.5-0.25 | Thermal conductivity of electric heating plate | 400-800 | 15-25 | 0.04-0.01 |

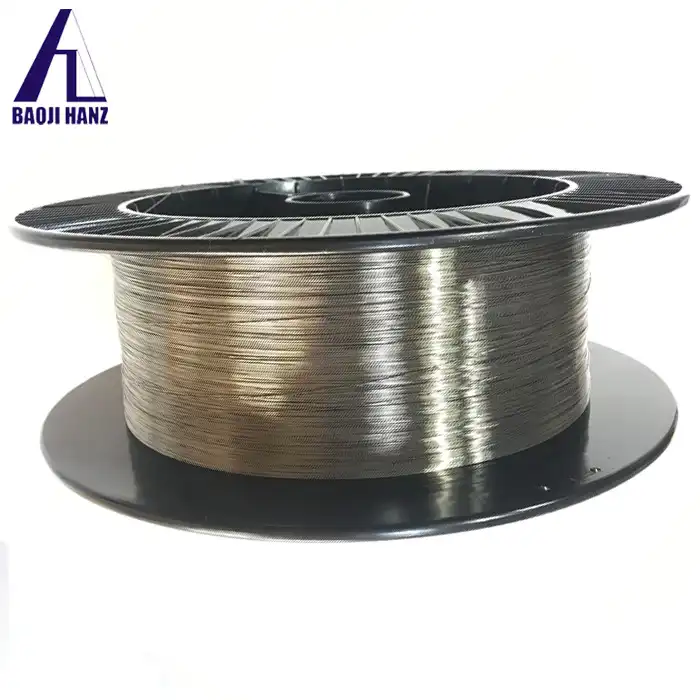

How to pack and ship Nitinol alloy wire?

To keep nitinol alloy wire safe when shipping, we always pack it tightly on spool and wrapped with foams, then put nitinol alloy wire spool in carton box and sealed it safely.

After all packed well, we mark each carton and arrange shipment by express, such as DHL, FedEx, UPS, etc.

FAQ

Q1: What is temperature range of nitinol alloy wire you can make?

A1: we can make different temperature range, AF-20-0C, AF0-20C, AF30-50C, AF60-80C

Q2: What surface of nitinol alloy wire you can mke?

A1: oxided surface, bright surface and black surface

Q3: What should i supply if ask a quotation?

A3: please inform us AF temperature, diameter, quantity and application.

Q4: What payment term do you use?

A4: we accept 100% T/T in advance, paypal, bank transfer are both ok.

Q5: Do you supply license of nitinol alloy wire?

A5: we provide chemical composition sheet, material testing report.

Contact us

Baoji Hanz supplies professional service of nitinol alloy wire sales, we offer high quality, best price and quick lead time for all clients.

welcome to inquire!

Email: baojihanz-06@hanztech.cn

_1750148477057.webp)