Nitinol ingot

Nickel titanium ingot refers to a metal ingot made of nickel titanium alloy (mainly Nitinol).

It can be understood as the primary form or semi-finished raw material of nickel titanium alloy material.

| Product name | Nitinol ingot |

| Af range | -10~10°C, 0~20°C, 20~40°C, 33+/-3°C, 40~60°C, 60~80°C, 80~100°C |

| MOQ | 10 kgs |

| Surface | oxided, polished |

| shape | bar, rod, cylinde, square, block |

| Standard | industry, medical |

| Application | medical, eyeglasses, mobile phone, medical device and so on |

| Payment term | 100% in advance |

| Payment method | paypal, bank transfer and so on |

| Production time | 25-35 workdays after payment confirmed. |

Ingredients of NiTi ingot:The main elements are nickel and titanium.

The most common alloys with shape memory and hyperelastic properties are near equimolar nickel titanium alloys, such as Ni-54~57.5 at% Ti. It may also contain small amounts of other elements (such as copper) to adjust its performance if customer required.

Accurate control of composition is crucial as it directly determines key properties such as shape memory temperature, hyperelastic plateau stress, and cycle life of the alloy.

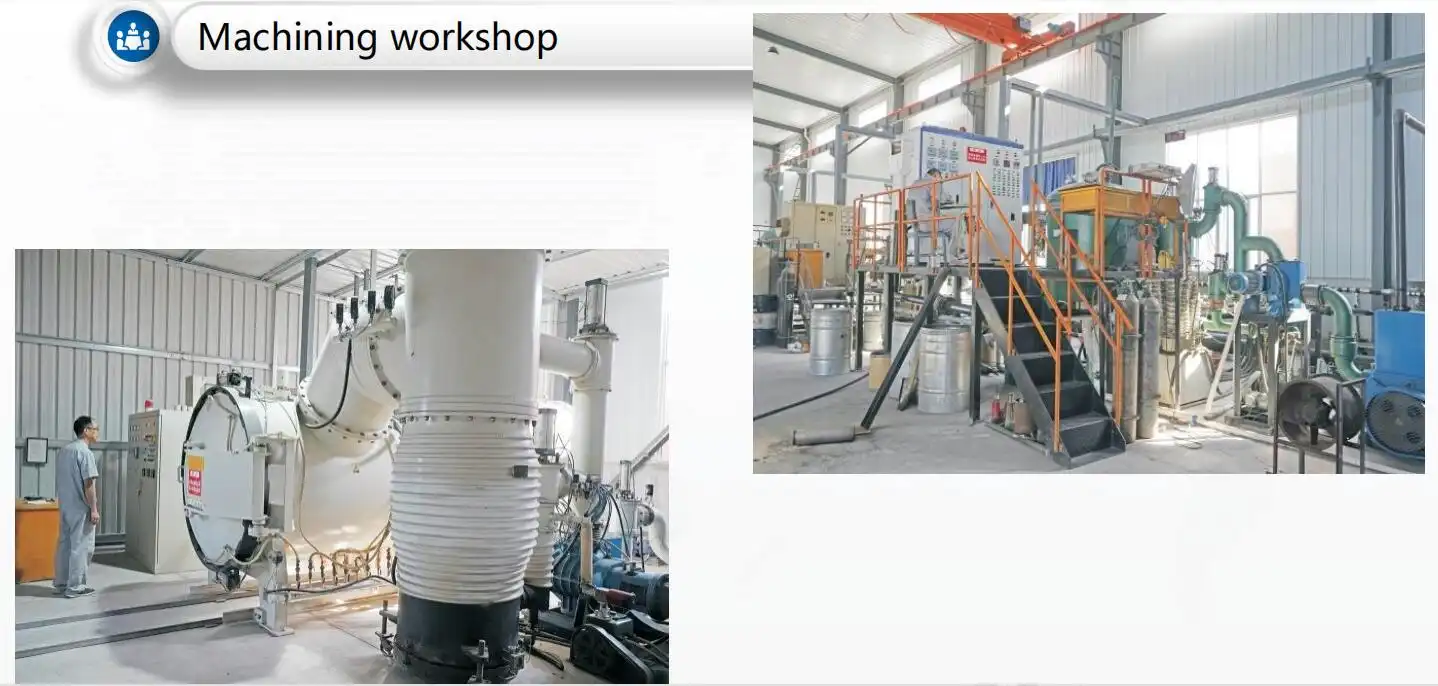

Nickel titanium ingot manufacturing process:Usually manufactured through vacuum melting processes, such as vacuum induction melting or vacuum arc remelting.

Melt high-purity nickel and titanium raw materials (possibly with other added elements) in precise proportions under vacuum or inert gas protection, and mix evenly.

Then pour the molten alloy into the mold, cool and solidify to form an ingot. Strict control is required during this process to avoid oxidation and impurities from entering.

|

|

|

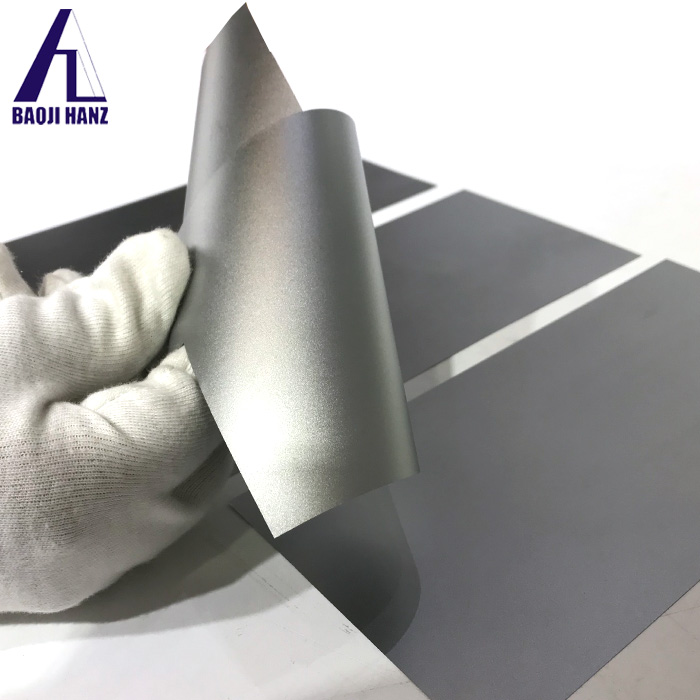

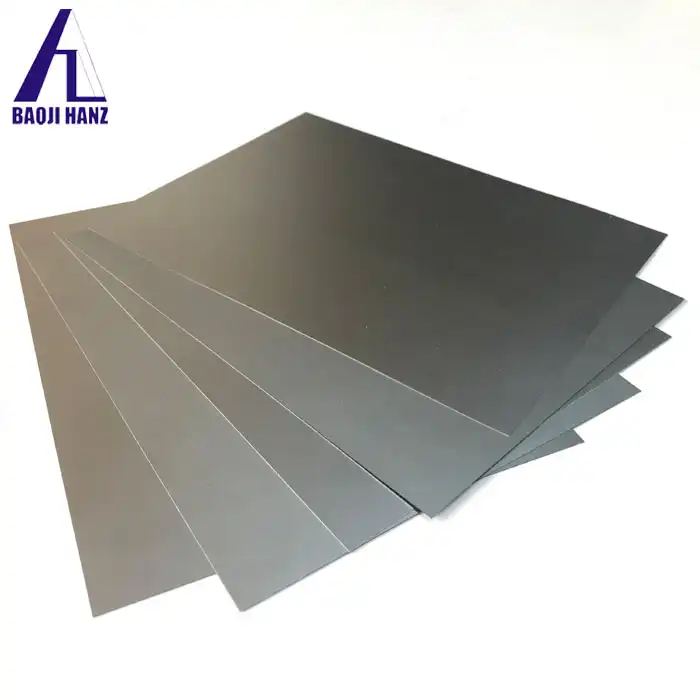

Nitinol ingot form:Usually cylindrical or rectangular block metal.

The size can range from a few kilograms to several hundred kilograms, depending on the production equipment and subsequent processing requirements.

The surface is usually rough and may have oxide scale or casting defects that need to be removed in subsequent processing.

Purpose and Application:Nickel titanium ingots are the starting point and basic raw materials for the subsequent processing and manufacturing of various nickel titanium alloy products.

Subsequent processing:Hot processing: hot forging, hot extrusion, hot rolling, etc., to break down coarse casting structures, increase density, and preliminarily form.

Cold processing: Cold drawing, cold rolling, etc., to obtain precise dimensions and shapes (such as wire, pipe, sheet, strip).

Heat treatment: solution treatment, aging treatment, shape memory training, etc., to set the final shape memory temperature, superelastic properties, and microstructure.

Final product applications:

Medical devices: vascular stents, guide wires, catheters, orthopedic instruments, orthodontic wires, surgical instruments, etc.

Aerospace: actuators, piping connections, seals, etc.

Industry: sensors, actuators, fasteners, robot components, etc.

Consumer electronics: eyeglass frames, mobile phone antennas (historically), foldable device hinges, etc.

Key characteristics (as raw materials):

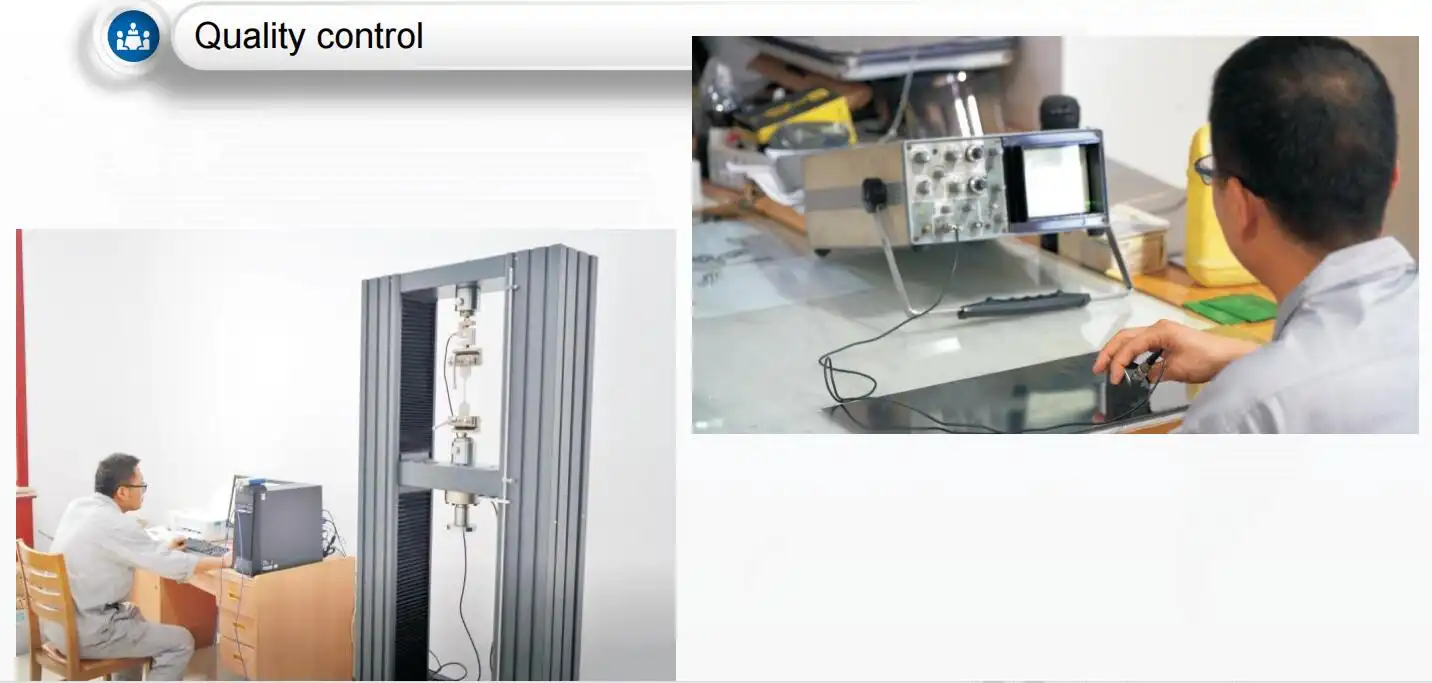

- Composition uniformity: Internal composition distribution must be highly uniform to ensure stable product performance.

- Purity: Extremely low impurity content (e.g., O, C, N) is essential to maintain mechanical properties, fatigue life, and corrosion resistance.

- Organizational density: Defects like porosity, shrinkage, and segregation must be minimized for quality and processability.

Contact Us

If you want to order nitinol ingot, please feel free to contact us by email: hztech05@hanztech.cn

_1753930177984.webp)

_1753930178041.webp)

_1753930177976.webp)

_1753930178030.webp)

_1753930177974.webp)

_1753930178038.webp)

_1751266472736.webp)

_1747884291962.webp)